- Home

- Products

- Hardness Tester

- Brinell Hardness Tester

Description

This Hardness Tester adopts hydraulic principle and applies 3000kgf test force by hand operation. The central part of this Hardness Tester is a small hydraulic system in which a release valve is used to control the test force. When the test force rises 3000kgf, the release valve will open and pressure will fall down, and it needs to apply the test force repeatedly 3-4 times to make the needle of the pressure gauge point to 3000kgf for 3-4 times.

Thus it is equivalent to the test condition of Brinell hardness testing method to hold 3000kgf test force with 10mm ball for 10-15 seconds, which complies with ASTM E110.

Application

- Aluminum

- Aluminum Alloys

- Soft Metals

- Plastics

- Fiberglass

- Fire Department Ladders

- Composite Materials

- Rubber or Leather

Features

- Test principle: Apply hydraulic principle permitting loading 3,000kgf manually.

- On-site Testing: It could be applied in workshop, simple operation, easy carrying, and testing body hardness of large parts piece by piece.

- Permanent Indentation: By 3,000kgf and 10mm test ball, the indentation is permanent for re-inspecting.

- High Reliability: It follows Brinell hardness test method completely, the same as desk testers, reflecting the actual mechanical property of material or parts.

- High Accuracy: Indication error, repeatability error and test force accuracy comply with ISO, and ASTM standards, the same as desk testers.

- Wide Application Range: As long as clamped to the parts, it could test parts in any shape and size.

- Wide Test Range: It could test various common metal materials by its combination of different test force and test head, that is, wide test range.

Specifications

| Model No. | BHB-3000 |

| Test Force | 3000kgf (1000kgf, 750kgf, 500kgf optional) |

| Test Ball | 10mm Carbide test ball (5mm optional) |

| Test Range | 32-650HBW |

| Opening Dimension | 350mm( Height)*100mm(Throat depth) |

| Indicator Error | Complies with ISO 6506, and ASTM E10 |

| Repeatability Error | Complies with ISO 6506, and ASTM E10 |

| Test Force Error | ≤ 1% and Complies with ISO 6506, and ASTM E10 |

Accessories

- Tester

- Handle

- Brinell Hardness Block

- Anvil (flat, V-type, spot-type )

- 20x Reading Microscope

- 10mm Spare Hard Alloy Test Ball

Software Description

Download Cataloge

ENQUIRY

Portable Brinell Hardness Tester

Description

BHB-3000A is very simple to operate and produce high accuracy. Install the test head into the chain adaptor, using the chain fix the tester on the surface of the specimen and apply the test force by pressure lever. The test head is a small hydraulic system that releases valve used to control the test force. When the test force rises to 3000kgf, the release valve will open and pressure will fall down. It needs to apply the test force repeatedly 3-4 times to make the needle of the pressure gage point to 3000kgf 3-4 times.

Thus, it is equivalent to the test condition of Brinell hardness testing method to hold 3000kgf test force with 10mm ball for 10-15 seconds which complies with ASTM E110

Application

Features

- It is a kind of Brinell hardness tester portably used in workshop, simple operation, easy carrying, and testing ontic hardness of large and cylindrical parts.

- By 3000kgf and 10mm ball, the indentation is permanent for re-inspection.

- BHB-3000achain hydraulic Brinell hardness tester follows the Brinell hardness test method completely, the same as desk testers, reflecting the actual mechanical property of material or parts

- The test force accuracy complies with relevant national and international standards, such as ISO 6506,ASTM E110, the same accuracy as desk tester.

Specifications

| Model No. | BHB-3000A |

| Testing Force | 3000kg (500kg, 750kg, 1000kg optional) |

| Indenter | Φ10mm carbide ball indenter (Φ 5mm available) |

| Testing Range | 32-650HBW |

| Test Force Error | ≤ 1% and Complies with ISO 6506, and ASTM E10 |

| Test Diameter | ≤ 500mm |

| Indication Error | Complies with ISO 6506 and ASTM E10 |

| Repeatability Error | Complies with ISO 6506 and ASTM E10 |

| Weight | 14.5 kg |

Accessories

- Tester

- Pressure Lever

- Brinell Hardness Test Block

- 20X reading Microscope

- 10mm Carbide Test Ball

- Chain Adapter

- Chain 1.3meter

- Brinell Indentation Measurement Software

Software Description

Download Cataloge

ENQUIRY

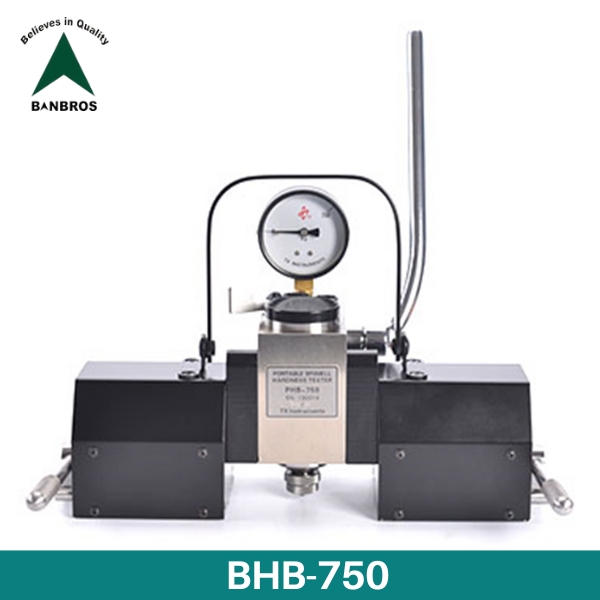

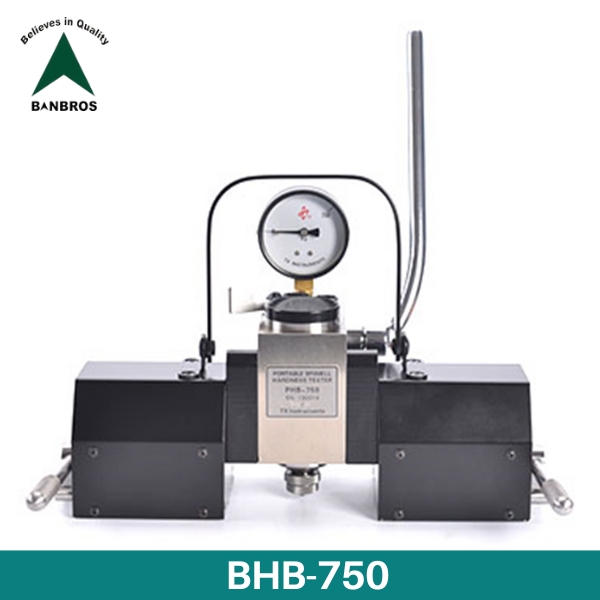

Portable Brinell Hardness Tester

Description

Fix the test head of hardness tester on the iron and steel part by the magnetic attractive force. The core part of this magnetic type Brinell tester is a small hydraulic system. The operator could actuate the hydraulic pump to produce 750kg test force by operating the pressure lever. There is a control valve in the hydraulic system which is used for controlling the test force. When the test force comes to 750kg, the control valve will immediately turn on and off, with the force falling down. According to the ASTM E110 and GB/T 4285, keep loading test force to make indicator hand points at 750kg for 3 to 4 times. It is an accurate and high qualified portable hardness tester for metal, and is equivalent to the regulation of Brinell hardness testing approach to hold test force for 10 to 15 seconds.

Application

- For casting, forging, steel plates, structural and die steel, which other tester could not test or hard to test.

- For macro axis, crossbeam, huge or super-huge heat treatment parts.

- For pipe, huge equipments and hug steel structural parts that welded or assembled already.

- Only for the magnetizer steel.

Features

- Test available if attached to one side of part.

- No need to move the part.

- No need to search for ascot for clamping.

- Test condition of 5mm test ball, 750 kgf test force, causes a larger indentation and better representativeness and easier to read than 2.5 mm test ball condition.

- Compared with other hydraulic Brinell hardness tester, simpler operation, easier to carry.

- If surface available, test materials, part and structural steel in any shape and size.

Specifications

| Model No. | BHB-750 |

| Test force | 750kg |

| Test ball | 5mm hard alloy ball |

| Test range | 100~650HBW |

| Indication error | Comply with ISO 6506, and ASTM E10. |

| Repeatability error | Comply with ISO 6506, and ASTM E10. |

| Test force error | Comply with ISO 6506, and ASTM E10. |

| Weight | 15.8kg |

| Surface | Flat: area ≥ 290mm × 90mm Cylinder: diameter ≥ 120mm |

Accessories

Software Description

Download Cataloge

ENQUIRY

Magnetic Hydraulic Brinell Hardness Tester

Description

Application

Features

- Small volume, convenient for carrying, easy operation

- Precision conforms to GB/T 231.2, ISO 6506-2 and ASTM E10

It can be used to determine the Brinell hardness of ferrous metals with elastic modulus approximate to 2×105 MPa. It is especially suitable to determine the hardness of heavy parts on the spot.

Measuring range: 100-400HBS

Impact capacity: 4.9J

Dimensions: Φ55 x 370mm

Weight: approx. 3.3kg

Specifications

Measuring range: 100-400HBS

Impact capacity: 4.9J

Dimensions: Φ55 x 370mm

Weight: approx. 3.3kg

Accessories

Portable Brinell standardized block: 1 pc.

20X Readout microscope: 1 pc.

Software Description

Download Cataloge

ENQUIRY

PORTABLE BRINELL HARDNESS TESTER