- Home

- Products

- Hardness Tester

- Micro Vicker Hardness Tester

Description

Application

Features

- Manual turret shifting between indenter and objective lens.

- Large LCD screen display, easy and convenient operation.

- Input D1 & D2 value from front panel and hardness value will be displayed on LCD directly.

- High quality integral casting cast iron machine body with automotive paint treatment process, the

- appearance is smooth and beautiful.

- The hardness scale, test force, indenter type, holding time and the conversion unit can be displayed on

- screen and set.

- The turbo-worm elevating system can greatly improve the testing stability and accuracy.

- HD measurement and observation - dual objective lens combination, combined with the HD

- micrometer eyepiece, greatly reduce the manual interference and reading error.

- Convenient control system can automatically convert the unit of full hardness scales.

- The maximum and minimum hardness values can be set, when the test value exceeds the set range, an

- alarm sound will be issued.

- The hardness value can be corrected within a certain range by standard scale.

- With the database function, the testing result can be saved automatically up to 200 data.

- CCD image measuring system is optional.

- Knoop indenter can be selected to measure the Knoop hardness.

- Equipped with wireless blue-tooth printer, the data can be output through RS232 or USB interface.

- Precision conforms to GB/T4340.2, ISO6507-2 and ASTM E384.

Specifications

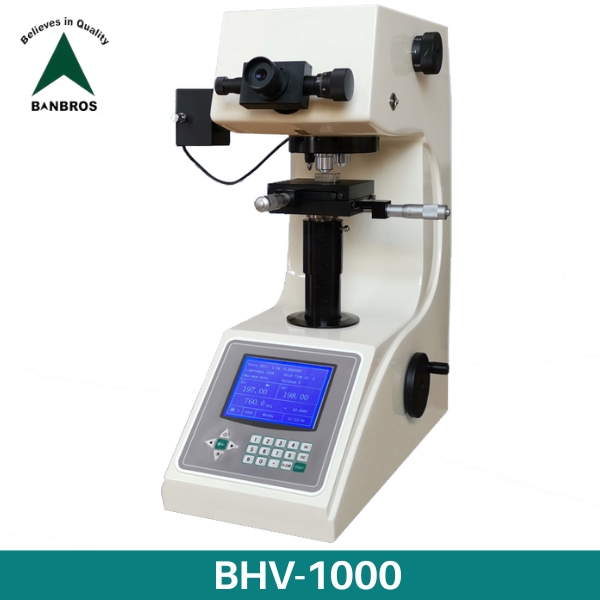

| Model No. | BHV-1000 |

| Test force | 10, 25, 50, 100, 200, 300, 500, 1000gf (0.09807, 0.2452, 0.4904, 0.9807, 1.961, 2.942, 4.904, 9.807N) |

| Conversion Scale |

HRA, HRB, HRC, HRD, HRE, HRF,HR15N, HR30N, HR45N, HR15T, HR30T,HR45T,HB, HV, |

| Hardness measuring range | 5~5000HV |

| Measuring resolution | 0.025μm |

| Hardness resolution | 0.1HV |

| Max Height of Specimen | 120mm |

| Depth of throat | 110mm |

| X-Y Testing table | Dimension: 100*100mm Max. travel: 25*25mm grade division of micrometer head: 0.01mm |

| Carried standards | GBT4340.2, ISO6507-2, ASTM E384 |

| Magnification of eyepiece | 10X |

| Magnification of objective lens |

10X, 40X |

| Total magnification | 100X, 400X |

| Data output | LCD display, wireless blue-tooth printer, RS232 and USB interface |

| Dwelling time | 1~99s |

| Power supply | AC 220V or 110V, 50 or 60Hz |

| Overall Dimensions | 530*290*490mm |

| Net weight | About 45Kg |

Accessories

- X-Y Coordinate test anvil : 1 pc

- Thin shaft anvil : 1 pc

- Thin plate anvil : 1 pc

- Flat nose pliers : 1 pc

- Large V-notch anvil : 1 pc

- Small V-notch anvil : 1 pc

- Diamond pyramid penetrator : 1 pc

- Micro-Vickers standardized block : 2 pcs

Software Description

Download Cataloge

ENQUIRY

Manual Turret Micro Vickers Hardness Tester

Description

It's suitable to determine the Vickers hardness of steel, non-ferrous metals, ceramics, treated layers of metal surface, and the hardness grads of carburized, nitrided and hardened layers of metals. It is and also suitable to determine the Vickers hardness of micro and super thin parts.

Application

Features

- Automatic turret shifting between indenter and objective lens. Large LCD screen display, easy and convenient operation.

- Input D1 & D2 value from front panel and hardness value will be displayed on LCD directly.

- High quality integral casting cast iron machine body with automotive paint treatment process, the appearance is smooth and beautiful.

- The hardness scale, test force, indenter type, holding time and the conversion unit can be displayed on screen and set.

- The turbo-worm elevating system can greatly improve the testing stability and accuracy.

- HD measurement and observation - dual objective lens combination, combined with the HD micrometer eyepiece, greatly reduce the manual interference and reading error.

- Convenient control system can automatically convert the unit of full hardness scales. The maximum and minimum hardness values can be set, when the test value exceeds the set range, an alarm sound will be issued.

- The hardness value can be corrected within a certain range by standard scale.

- With the database function, the testing result can be saved automatically up to 200 data. CCD image measuring system is optional.

- Knoop indenter can be selected to measure the Knoop hardness.

- Equipped with wireless blue-tooth printer, the data can be output through RS232 or USB interface.

- Precision conforms to GB/T4340.2, ISO6507-2 and ASTM E384.

- It can be used to determine the Vickers hardness of steel, non-ferrous metals, ceramics, treated layers of metal surface, and the hardness grads of carburized, nitrided and hardened layers of metals. It is also suitable to determine the Vickers hardness of micro and super thin parts.

Specifications

|

Model No. |

BHV-1000A | |

| Test force | 10, 25, 50, 100, 200, 300, 500, 1000gf (0.09807, 0.2452, 0.4904, 0.9807, 1.961, 2.942, 4.904, 9.807N) | |

| Conversion Scale | HRA, HRB, HRC, HRD, HRE, HRF, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HB, HV | |

| Hardness measuring range | 5~5000HV | |

| Measuring resolution | 0.025μm | |

| Hardness resolution | 0.1HV | |

| Max Height of Specimen | 120mm | |

| Depth of throat | 110mm | |

| X-Y Testing table | Dimension: 100*100mm Max. travel: 25*25mm grade division of micrometer head: 0.01mm |

|

| Carried standards | GBT4340.2, ISO6507-2, ASTM E384 | |

| Magnification of eyepiece | 10X | |

| Magnification of objective lens | 10X, 40X | |

| Total magnification | 100X, 400X | |

| Data output | LCD display, wireless blue-tooth printer, RS232 and USB interface | |

| Dwelling time | 1~99s | |

| Power supply | AC 220V or 110V, 50 or 60Hz | |

| Overall Dimensions | 530*290*490mm | |

| Net weight | About 45Kg | |

Accessories

- X-Y Coordinate test anvil : 1 pc. Thin shaft anvil: 1 pc

- Thin plate anvil : 1 pc

- Flat nose pliers : 1 pc

- Large V-notch anvil : 1 pc

- Small V-notch anvil : 1 pc

- Diamond pyramid penetrator : 1 pc

- Micro-Vickers standardized block : 2 pcs

Software Description

Download Cataloge

ENQUIRY

Auto Turret Micro Vickers Hardness Tester

Description

It's suitable to determine the Vickers hardness of steel, non-ferrous metals, ceramics, treated layers of metal surface, and the hardness grads of carburized, nitrided and hardened layers of metals. It is and also suitable to determine the Vickers hardness of micro and super thin parts.

Application

Features

- Automatic turret shifting between indenter and objective lens.

- Large 8” touch screen, direct visual display and interactive operating interface.

- Input D1 & D2 value from touch screen and hardness value will be displayed on LCD directly.

- High speed ARM processor, fast operation speed and extensive database storage.

- High quality integral casting cast iron machine body with automotive paint treatment process, the appearance is smooth and beautiful.

- The hardness scale, test force, indenter type, holding time and the conversion unit can be displayed on screen and set.

- The turbo-worm elevating system can greatly improve the testing stability and accuracy.

- HD measurement and observation - dual objective lens combination, combined with the HD

- micrometer eyepiece, greatly reduce the manual interference and reading error.

- Convenient control system can automatically convert the unit of full hardness scales.

- The maximum and minimum hardness values can be set, when the test value exceeds the set range, an alarm sound will be issued.

- With the function of software hardness value correction, the hardness value can be directly corrected within a certain range.

- With the database function, the testing data can be saved automatically in groups, each group can save 10 data, totally can save up to 2000 data.

- With the hardness value curve display function, intuitively display the changes of hardness value.

- CCD image measuring system is optional.

- Knoop indenter can be selected to measure the Knoop hardness.

- Equipped with wireless blue-tooth printer, the data can be output through RS232 or USB interface.

- Precision conforms to GB/T4340.2, ISO6507-2 and ASTM E384.

- It can be used to determine the Vickers hardness of steel, non-ferrous metals, ceramics, treated layers of metal surface, and the hardness grads of carburized, nitrided and hardened layers of metals. It is also suitable to determine the Vickers hardness of micro and super thin parts.

Specifications

| Model No. | BHV-1000TA |

| Test force | 10, 25, 50, 100, 200, 300, 500, 1000gf (0.09807, 0.2452, 0.4904, 0.9807, 1.961, 2.942, 4.904, 9.807N) |

| Conversion Scale | HRA, HRB, HRC, HRD, HRE, HRF, HV, HB, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T |

| Hardness measuring range | 5~2900HV |

| Measuring resolution | 0.025μm |

| Hardness resolution | 0.1HV |

| Max Height of Specimen | 120mm |

| Depth of throat | 110mm |

| X-Y Testing table | Dimension: 100*100mm Max. travel: 25*25mm grade division of micrometer head: 0.01mm |

| Carried standards | GBT4340.2, ISO6507-2, ASTM E384 |

| Magnification of eyepiece | 10X |

| Magnification of objective lens | 10X, 40X |

| Total magnification | 100X, 400X |

| Data output | LCD display, wireless blue-tooth printer, RS232 and USB interface |

| Dwelling time | 1~99s |

| Power supply | AC 220V or 110V, 50 or 60Hz |

| Overall Dimensions | 530*290*490mm |

| Net weight | About 45Kg |

Accessories

- X-Y Coordinate test anvil : 1 pc. Thin shaft anvil: 1 pc.

- Thin plate anvil : 1 pc.

- Flat nose pliers : 1 pc.

- Large V-notch anvil : 1 pc.

- Small V-notch anvil : 1 pc.

- Diamond pyramid penetrator : 1 pc.

- Micro-Vickers standardized block : 2 pcs.

Software Description

Download Cataloge

ENQUIRY

Auto Turret Touch Screen Micro Vickers Hardness Tester

Description

It's suitable to determine the Vickers hardness of steel, non-ferrous metals, ceramics, treated layers of metal surface, and the hardness grads of carburized, nitrided and hardened layers of metals. It is and also suitable to determine the Vickers hardness of micro and super thin parts.

Application

Features

- Automatic turret shifting between indenter and objective lens.

- Large LCD screen display, easy and convenient operation.

- High quality integral casting cast iron machine body with automotive paint treatment process, the appearance is smooth and beautiful.

- The hardness scale, test force, indenter type, holding time and the conversion unit can be displayed on screen and set.

- The turbo-worm elevating system can greatly improve the testing stability and accuracy.

- HD measurement and observation - dual objective lens combination, combined with the built-in length encoder HD micrometer eyepiece, to achieve indentation diagonal one-key measurement, greatly reduce the manual interference and reading error.

- Convenient control system can automatically convert the unit of full hardness scales.

- The maximum and minimum hardness values can be set, when the test value exceeds the set range, an alarm sound will be issued.

- The hardness value can be corrected within a certain range by standard scale.

- With the database function, the testing result can be saved automatically up to 200 data. CCD image measuring system is optional.

- Knoop indenter can be selected to measure the Knoop hardness.

- Equipped with wireless blue-tooth printer, the data can be output through RS232 or USB interface.

- Precision conforms to GB/T4340.2, ISO6507-2 and ASTM E384.

- It can be used to determine the Vickers hardness of steel, non-ferrous metals, ceramics, treated layers of metal surface, and the hardness grads of carburized, nitrided and hardened layers of metals. It is also suitable to determine the Vickers hardness of micro and super thin parts.

Specifications

| Model No. | BHVS-1000A |

| Test force | 10, 25, 50, 100, 200, 300, 500, 1000gf (0.09807, 0.2452, 0.4904, 0.9807, 1.961, 2.942, 4.904, 9.807N) |

| Conversion Scale | HRA, HRB, HRC, HRD, HRE, HRF, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HB, HV |

| Hardness measuring range | 5~5000HV |

| Measuring resolution | 0.025μm |

| Hardness resolution | 0.1HV |

| Max Height of Specimen | 120mm |

| Depth of throat | 110mm |

| X-Y Testing table | Dimension: 100*100mm Max. travel: 25*25mm grade division of micrometer head: 0.01mm |

| Carried standards | GBT4340.2, ISO6507-2, ASTM E384 |

| Magnification of eyepiece | 10X |

| Magnification of objective lens | 10X, 40X |

| Total magnification | 100X, 400X |

| Data output | LCD display, wireless blue-tooth printer, RS232 and USB interface |

| Dwelling time | 1~99s |

| Power supply | AC 220V or 110V, 50 or 60Hz |

| Overall Dimensions | 530*290*490mm |

| Net weight | About 45Kg |

Accessories

- X-Y Coordinate test anvil : 1 pc.

- Thin shaft anvil : 1 pc.

- Thin plate anvil : 1 pc.

- Flat nose pliers : 1 pc.

- Large V-notch anvil : 1 pc.

- Small V-notch anvil : 1 pc.

- Diamond pyramid penetrator : 1 pc.

- Micro-Vickers standardized block : 2 pcs.

Software Description

Download Cataloge

ENQUIRY

Auto Turret Digital Display Micro Vickers Hardness Tester

Description

It's suitable to determine the Vickers hardness of steel, non-ferrous metals, ceramics, treated layers of metal surface, and the hardness grads of carburized, nitrided and hardened layers of metals. It is and also suitable to determine the Vickers hardness of micro and super thin parts.

Application

Features

- Automatic turret shifting between indenter and objective lens.

- Large 8” touch screen, direct visual display and interactive operating interface.

- High speed ARM processor, fast operation speed and extensive database storage.

- High quality integral casting cast iron machine body with automotive paint treatment process, the appearance is smooth and beautiful.

- The hardness scale, test force, indenter type, holding time and the conversion unit can be displayed on screen and set.

- The turbo-worm elevating system can greatly improve the testing stability and accuracy.

- HD measurement and observation - dual objective lens combination, combined with the built-in length encoder HD micrometer eyepiece, to achieve indentation diagonal one-key measurement, greatly reduce the manual interference and reading error.

- Convenient control system can automatically convert the unit of full hardness scales.

- The maximum and minimum hardness values can be set, when the test value exceeds the set range, an alarm sound will be issued.

- With the function of software hardness value correction, the hardness value can be directly corrected within a certain range.

- With the database function, the testing data can be saved automatically in groups, each group can save 10 data, totally can save up to 2000 data.

- With the hardness value curve display function, intuitively display the changes of hardness value.

- CCD image measuring system is optional.

- Knoop indenter can be selected to measure the Knoop hardness.

- Equipped with wireless blue-tooth printer, the data can be output through RS232 or USB interface.

- Precision conforms to GB/T4340.2, ISO6507-2 and ASTM E384.

- It can be used to determine the Vickers hardness of steel, non-ferrous metals, ceramics, treated layers of metal surface, and the hardness grads of carburized, nitrided and hardened layers of metals. It is also suitable to determine the Vickers hardness of micro and super thin parts.

Specifications

| Model No | BHVS-1000TA |

| Test force | 10, 25, 50, 100, 200, 300, 500, 1000gf (0.09807, 0.2452, 0.4904, 0.9807, 1.961, 2.942, 4.904, 9.807N) |

| Conversion Scale | HRA, HRB, HRC, HRD, HRE, HRF, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HB, HV, HS |

| Hardness measuring range | 5~5000HV |

| Measuring resolution | 0.025μm |

| Hardness resolution | 0.1HV |

| Max Height of Specimen | 120mm |

| Depth of throat | 110mm |

| X-Y Testing table | Dimension: 100*100mm Max. travel: 25*25mm grade division of micrometer head: 0.01mm |

| Carried standards | GBT4340.2, ISO6507-2, ASTM E384 |

| Magnification of eyepiece | 10X |

| Magnification of objective lens | 10X, 40X |

| Total magnification | 100X, 400X |

| Data output | LCD display, wireless blue-tooth printer, RS232 and USB interface |

| Dwelling time | 1~99s |

| Power supply | AC 220V or 110V, 50 or 60Hz |

| Overall Dimensions | 530*290*490mm |

| Net weight | Net weight |

Accessories

- X-Y Coordinate test anvil : 1 pc.

- Thin shaft anvil : 1 pc.

- Thin plate anvil : 1 pc.

- Flat nose pliers : 1 pc.

- Large V-notch anvil : 1 pc.

- Small V-notch anvil : 1 pc.

- Diamond pyramid penetrator : 1 pc.

- Micro-Vickers standardized block : 2 pcs.

Software Description

Download Cataloge

ENQUIRY

Auto Turret Touch Screen Digital Display Micro Vickers Hardness Tester

Description

High-quality imported components, ensure the new type Micro Hardness Testers working more stable. Protected by the state patent application of the lift & down system, after upgrading, the control system can provide more measuring data, and control more precise. This machine is integrated with optics, mechanics and electricity. It with unbeatable price / performance ratio, widely used in quality inspection and quality control field.

- One time casting aluminum body with sturdy structure, modular design and stable working performance

- Load from 10 to 1000g, can extend to 2kgf

- Precise manual analog 10X eyepiece

- With hardness conversion function

- LED Cold light source

- Dual optical path, can work with hardness measurement software system (optional purchase)

- Standard machine come with Precision screw rod lifting system (Worm gear rod lifting system for optional purchase)

Application

- Steel, nonferrous metals, tinsel, cemented carbide, sheet metal, metallographic structure.

- Carburization, nit riding and decarburization layer, surface hardening layer, galvanized coating, coating.

- Glass, chip and ceramic material.

Features

- Main components adopted American 3M, Allegro, and Japanese Omron, NKK brand, ensure the instrument can stable working for a very long time.

- Adopted one time casting aluminum machine body and car painting technology, structure more stable and appearance more decent.

- The independent research and development of lift & down system and positioning system, ensured the accuracy and repeatedly of the testing process.

- The optical system designed by our senior optical engineer not only meet the definition of hardness testing requirements, but also can observe the micro structure of the material, image is very clear.

- According to different visual habits of the operators, the strength of the light source can be adjusted. To avoid the visual fatigue for long time operation.

- With Vickers hardness and Knoop hardness testing capabilities. By measuring the indentation diagonal length, the hardness will show on the screen directly, no need to check hardness table.

- Industrial digital screen can direct display hardness value, conversion hardness value, testing method, testing force, dwell time, easy for operator to save the data.

- Double optical path design. Both eyepiece and CCD camera path can work at same time. No need switch optical path. Camera can be install inside machine (camera for optional purchase).

Specifications

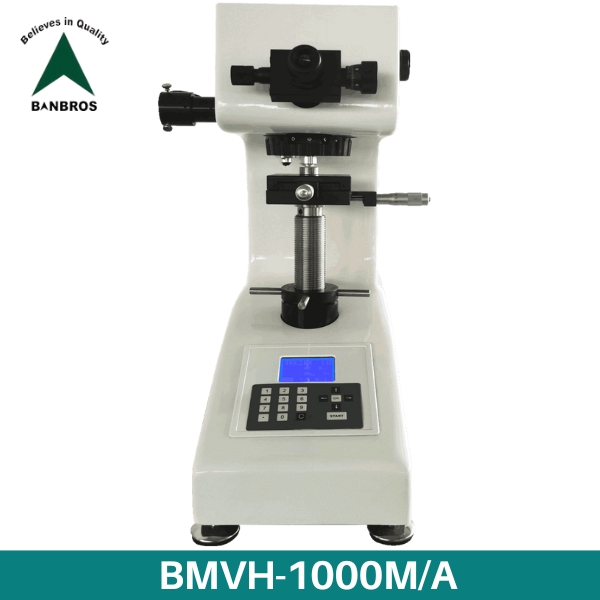

| Model No. | BMVH-1000M | BMVH-1000A |

| Turret | Manual Turret | Automatic Turret |

| Testing force | 10g(0.098N), 25g(0.245N), 50g(0.49N), 100g(0.98N ), 200g(1.96N), 300g(2.94N), 500g(4.9N), 1kg(9.8N) | |

| Hardness scale | HV0.01, HV0.025, HV0.05, HV0.1, HV0.2, HV0.3, HV0.5, HV1 | |

| Loading speed | ≤0.05mm/sec | |

| Indenter | Standard Rectangular pyramid diamond indenter (136º±0.5º) | |

| Min. measuring unit | 0.25μm | |

| Hardness value rang | 5HV-3000HV | |

| Hardness Value of Reading | Digital LCD Screen | |

| Eyepiece | 10X manual analog eyepiece | |

| Objective lens | 10X (observe), 40X (Measurement) | |

| Total magnification | 100X (For Observation) , 400X (For Measurement) | |

| Loading method | Automatically (Load, dwell and unload the testing force) | |

| Duration time | 1-99s (each step is 1 second) | |

| Maximum height | 90mm | |

| Throat depth | 95mm | |

| Instrument size and Net weight | 405*290*480mm (L×W×H) & 40kg | |

| Packing size and Gross weight | 580x345x580mm( LxWxH) & 55kg | |

| Light Source | LED cold light source | |

| Power Supply | 220V + 5%, 50/60 Hz (110V is available) | |

| X-Y Testing Table | Dim.:100×100 mm, Max. Travel Range:25×25mm, Moving Resolution Ratio: 0.01mm | |

| Executed Standard | GB/T4340, ASTM E384 & E92, EN-ISO 6507, JIS B-7734 | |

Accessories

- Weights shaft : 1 pc

- sheet specimen fixture : 1 pc

- 10X manual micrometer eyepiece : 1 pc

- Power line : 1 pc

- 10X and 40X objective lens : 1 pc

- Dust proof cover : 1 pc

- Vickers diamond indenter : 1 pc

- Manual Book : 1 pc

- X-Y Testing Table : 1 pc

- Certificate of quality : 1 pc

- Gradienter : 1 pc

- Screwdriver : 1 pc

- Flat fixture : 1 pc

- Warranty Card : 1 pc

- Accessory box : 1 pc

- Spare fuse : 2 pcs

- Standard block of hardness : 2 pcs

- horizontal adjusting screw : 4 pcs

*Optional Accessories:

- Image analysis software

- Metallographic equipment

- Knoop Indenter; hardness block

- 15X micrometer eyepiece

- Thin Specimen Test Table

- Flat fixture

- Filament Clamping Test Table

Software Description

Download Cataloge

ENQUIRY

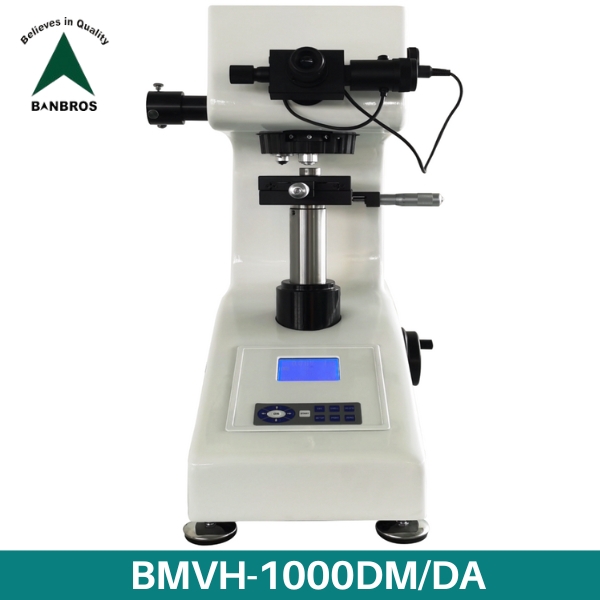

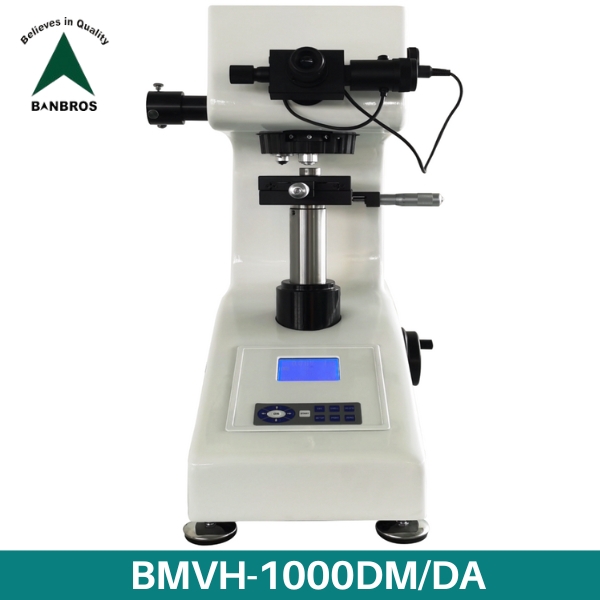

Manual/Automatic Turret Micro Vickers Hardness Tester

Description

Application

- Steel, nonferrous metals, tinsel, cemented carbide, sheet metal, metallographic structure.

- Carburization, nitriding and decarburization layer, surface hardening layer, galvanized coating.

- Glass, chip and ceramic material.

Features

- One-time casting aluminum machine body with car painting technology, structure more stable and appearance more decent.

- With large screen LCD screen display, directly display hardness value, dwell time, conversion hardness value, etc.

- Menu structure interface, easy operation.

- With HV / HK test function (if need HK test function, optional purchase Knoop diamond indenter and standard hardness blocks).

- Digital eyepiece with encoder, only click the button on encoder, the D1, D2 value will input machine automatically. No need manually input the value of diagonal length. Easy operation, greatly improve working efficiency, and test result more accurate.

- With built-in printer, test result can be printed out directly.

- With RS232 communication port, purchase our data transfer software via RS232 port can save test data to computer and by software can control machine (for Automatic turret machine).

- Double optical path design. Both eyepiece and CCD camera path can work at same time. No need switch optical path. Camera can be install inside machine (camera for optional purchase).

Specifications

| Model No. | BMVH-1000DM | BMVH-1000DA |

| Turret | Manual turret | Automatic turret |

| Test force | 10gf (0.098N), 25gf (0.245N), 50gf (0.49N), 100gf (0.98N), 200gf (1.96N), 300gf (2.94N), 500gf(4.9N), 1kgf (9.8N) | |

| Hardness scale | HV0.01, HV0.025, HV0.05, HV0.1, HV0.2, HV0.3, HV0.5, HV1 | |

| Conversion Scale | HRA, HRB, HRC, HRD, HRF, HV, HK, HBW, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T | |

| Hardness range | 5-3000HV | |

| Min measuring unit | 0.01µm | |

| Data display | LCD screen | |

| Data output | built-in printer, RS-232 port | |

| Maximum height allowed for testing | 90mm | |

| Throat depth | 95mm | |

| X-Y Testing table | Dimension: 100x100mm Max movement: 25x25mm | |

| Force loading type | Automatic (Loading, Dwell, Unloading) | |

| Magnification | Eyepiece: 10X; Objective: 10X (observation use); 40X (measuring use) Total: 100X (observation); 400X (Measuring) |

|

| Duration time | 1~99s | |

| Power supply | AC220V±5%, 50-60Hz | |

| Machine size | 405*290*480mm; Net weight: 40kg | |

| Package size | 530x350x820mm; Gross weight: 59kg | |

Accessories

- Weight shaft : 1 pc

- X-Y Cross clamping testing table : 1 pc

- Filament clamping testing table : 1 pc

- Printer paper : 1 pc

- Gradienter : 1 pc

- Micro Vickers hardness block : 2 pcs

- Dust-proof cover : 1 pc

- Power cable : 1 pc

- Manual : 1 pc

- Weights : 6 pcs

- Flat clamping testing table : 1 pc

- Thin Specimen Testing Table : 1 pc

- Level adjustment screw : 4 pcs

- Objective 10X, 40X : 1+1 pc

- Eyepiece 10X : 1 pc

- Screw driver : 2 pcs

- Fuse (2A) : 2 pcs

- Product Certificate : 1 pcs

Software Description

Download Cataloge

ENQUIRY

Digital Micro Vickers Hardness Tester

Description

Application

- Steel, nonferrous metals, tinsel, cemented carbide, sheet metal, metallographic structure.

- Carburization, nitriding and decarburization layer, surface hardening layer, galvanized coating, coating.

- Glass, chip and ceramic material.

Features

- One-time casting aluminum machine body with car painting technology, structure more stable and appearance more decent.

- With large screen LCD screen display, directly display hardness value, dwell time, conversion hardness value, etc.

- Menu structure interface, easy operation.

- With HV / HK test function (if need HK test function, optional purchase Knoop diamond indenter and standard hardness blocks).

- Digital eyepiece with encoder, only click the button on encoder, the D1, D2 value will input machine automatically. No need manually input the value of diagonal length. Easy operation, greatly improve working efficiency, and test result more accurate.

- With built-in printer, test result can be printed out directly.

- With RS232 communication port, purchase our data transfer software via RS232 port can save test data to computer and by software can control machine (for Automatic turret machine).

- Double optical path design. Both eyepiece and CCD camera path can work at same time. No need switch optical path. Camera can be install inside machine (camera for optional purchase).

Specifications

| Model No. | BMVH-1000-1BM | BMVH-1000-1BA |

| Turret | Manual turret | Automatic turret |

| Test force | 10gf (0.098N), 25gf (0.245N), 50gf (0.49N), 100gf (0.98N), 200gf (1.96N), 300gf (2.94N), 500gf(4.9N), 1kgf (9.8N) |

|

| Hardness scale | HV0.01, HV0.025, HV0.05, HV0.1, HV0.2, HV0.3, HV0.5, HV1 | |

| Conversion Scale | HRA, HRB, HRC, HRD, HRF, HV, HK, HBW, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T |

|

| Hardness range | 1-4000HV | |

| Min measuring unit | 0.01µm | |

| Data display | Large LCD screen | |

| Data output | built-in printer, RS-232 port | |

| Test space | 90mm * 95mm (Height * Throat Depth) | |

| X-Y Testing table | Dimension: 100x100mm Max movement: 25x25mm | |

| Force loading type | Automatic (Loading, Dwell, Unloading) | |

| Magnification | Eyepiece: 10X; Objective: 10X (observation use); 40X (measuring use); Total: 100X (observation); 400X (Measuring) | |

| Duration time | 1~99s | |

| Power supply | AC220V±5%, 50-60Hz | |

| Machine size | 405*290*480mm; Net weight: 40kg | |

| Package size | 550x370x720mm; Gross weight: 56kg | |

Accessories

- Weight shaft : 1 pc

- Weights : 6 pcs

- X-Y Cross clamping testing table : 1 pcs

- Flat clamping testing table : 1 pc

- Thin Specimen Testing Table : 1 pc

- Micro Vickers hardness block : 2 pcs

- Printer paper : 1 pc

- Level adjustment screw : 4 pcs

- Gradienter : 1 pc

- Objective 10X, 40X : 1+1 pc

- Power cable : 1 pc

- Eyepiece 10X : 1 pc

- Dust-proof cover : 1 pc

- Screw driver : 2 pcs

- Fuse (2A) : 2 pcs

- Manual Book & Quality Certificate : 1 pc

Software Description

Download Cataloge

ENQUIRY

Digital Micro Vickers Hardness Tester With Multifunctional Large Screen

Description

Application

- Steel, nonferrous metals, tinsel, cemented carbide, sheet metal, metallographic structure.

- Carburization, nitriding and decarburizationlayer, surface hardening layer, galvanized coating.

- Glass, chip and ceramic material.

Features

- Adopted one time casting aluminum machine body and car painting technology, structure more stable and appearance more decent.

- The independent research and development of lift & down system and positioning system, ensured the accuracy and repeatedly of the testing process.

- The optical system designed by our senior optical engineer not only meet the definition of hardness testing requirements, but also can observe the micro structure of the material, image is very clear.

- According to different visual habits of the operators, the strength of the light source can be adjusted. To avoid the visual fatigue for long time operation.

- With Vickers hardness and Knoop hardness testing capabilities. By measuring the indentation diagonal length, the hardness will show on the screen directly, no need to check hardness table.

- Industrial digital touch screen can direct display hardness value, conversion hardness value, testing method, testing force, dwell time, easy for operator to save the data.

- Double optical path design. Both eyepiece and CCD camera path can work at same time. No need switch optical path. Camera can be install inside machine (camera for optional purchase).

Specifications

| Model No. | BMVH-1000MT | BMVH-1000AT |

| Turret | Manual Turret | Automatic Turret |

| Testing force | 10g (0.098N), 25g (0.245N), 50g (0.49N), 100g (0.98N ), 200g (1.96N), 300g (2.94N), 500g (4.9N), 1000g (9.8N) Test force error: ±1.0% | |

| Hardness scale | HV0.01, HV0.025, HV0.05, HV0.1, HV0.2, HV0.3, HV0.5, HV1 | |

| Loading speed | ≤0.05mm/sec | |

| Indenter | Standard Rectangular pyramid diamond indenter (136º±0.5º) | |

| Min. measuring unit | 0.25μm | |

| Hardness value rang | 5HV-3000HV | |

| Hardness Value of Reading | Digital LCD Screen | |

| Eyepiece | 10X manual analog eyepiece | |

| Objective lens | 10X (observe), 40X (Measurement) | |

| Total magnification | 100X (For Observation) , 400X (For Measurement) | |

| Loading method | Automatically (Load, dwell and unload the testing force) | |

| Duration time | 1-60s (each step is 1 second) | |

| Maximum height | 90mm | |

| Throat depth | 95mm | |

| Instrument size and Net weight | 405*290*480mm (L×W×H) 40kg | |

| Packing size and Gross weight | 580x345x580mm( LxWxH) 55kg | |

| Light Source | LED cold light source | |

| Power Supply | 220V + 5%, 50/60 Hz (110V is available) | |

| X-Y Testing Table | Dim.:100×100 mm, Max. Travel Range: 25×25mm, Moving Resolution Ratio: 0.01mm | |

| Executed Standard | GB/T4340, ASTM E384 & E92, EN-ISO 6507, JIS B-7734 | |

Accessories

- Weights shaft : 1 pc

- Weights : 6 pcs

- 10X manual micrometer eyepiece : 1 pc

- 10X objective lens : 1 pc

- 40X objective lens : 1 pc

- Vickers diamond indenter : 1 pc

- X-Y Testing Table : 1 pc

- Flat fixture : 1 pc

- Sheet specimen fixture : 1 pc

- Standard block of hardness : 2 pcs

- Spare fuse 2A : 2 pcs

- Horizontal adjusting screw : 4 pcs

- Power line : 1 pc

- Dust proof cover : 1 pc

- Manual Book : 1 pc

- Certificate of quality : 1 pc

- Screwdriver : 2 pcs

- Warranty Card : 1 pc

- Accessory box : 1 pc

- Level bubble Note: For avoid potential risks, Will remove level bubble if ship by air, since liquid materials are forbidden by airlines : 1 pc

Software Description

Download Cataloge

ENQUIRY

Micro Vickers Hardness Tester With Touch Screen

Description

Application

- Steel, nonferrous metals, tinsel, cemented carbide, sheet metal, metallographic structure.

- Carburization, nitriding and decarburization layer, surface hardening layer, galvanized coating.

- Glass, chip and ceramic material.

Features

- One-time casting aluminum machine body with car painting technology, structure more stable and appearance more decent.

- With large screen LCD screen display, directly display hardness value, dwell time, conversion hardness value, etc.

- Menu structure interface, easy operation.

- With HV / HK test function (if need HK test function, optional purchase Knoop diamond indenter and standard hardness blocks).

- Digital eyepiece with encoder, only click the button on encoder, the D1, D2 value will input machine automatically. No need manually input the value of diagonal length. Easy operation, greatly improve working efficiency, and test result more accurate.

- With built-in printer, test result can be printed out directly.

- With RS232 communication port, purchase our data transfer software via RS232 port can save test data to computer and by software can control machine (for Automatic turret machine)

- Double optical path design. Both eyepiece and CCD camera path can work at same time. No need switch optical path. Camera can be install inside machine (camera for optional purchase).

Specifications

| Model No. | BMVH-1000-1MT | BMVH-1000-1AT |

| Turret | Manual Turret | Automatic Turret |

| Testing force | 10g (0.098N), 25g (0.245N), 50g (0.49N), 100g (0.98N ), 200g (1.96N), 300g (2.94N), 500g (4.9N), 1000g (9.8N) Test force error: ±1.0% | |

| Hardness scale | HV0.01, HV0.025, HV0.05, HV0.1, HV0.2, HV0.3, HV0.5, HV1 | |

| Loading speed | ≤0.05mm/sec | |

| Indenter | Standard Rectangular pyramid diamond indenter (136º±0.5º) | |

| Min. measuring unit | 0.01μm | |

| Hardness value rang | 5HV-3000HV | |

| Hardness Value of Reading | Digital LCD Screen | |

| Eyepiece | 10X digital eyepiece | |

| Objective lens | 10X (observe), 40X (Measurement) | |

| Total magnification | 100X (For Observation) , 400X (For Measurement) | |

| Loading method | Automatically (Load, dwell and unload the testing force) | |

| Duration time | 1-99s (each step is 1 second) | |

| Maximum height | 90mm | |

| Throat depth | 95mm | |

| Instrument size and Net weight | 405*290*480mm (L×W×H) 40kg | |

| Packing size and Gross weight | 580x345x580mm( LxWxH) 55kg | |

| Light Source | LED cold light source | |

| Power Supply | 220V + 5%, 50/60 Hz (110V is available) | |

| X-Y Testing Table | Dim.:100×100 mm, Max. Travel Range: 25×25mm, Moving Resolution Ratio: 0.01mm | |

| Executed Standard | GB/T4340, ASTM E384 & E92, EN-ISO 6507, JIS B-7734 | |

| Optional Purchase Accessories | Image analysis software; Metallographic equipment; Knoop Indenter; hardness block; 15X micrometer eyepiece, Filament Clamping Test Table | |

Accessories

- Weights shaft : 1 pc

- Weights : 6 pcs

- 10X digital eyepiece : 1 pc

- 10X objective lens : 1 pc

- 40X objective lens : 1 pc

- Vickers diamond indenter : 1 pc

- X-Y Testing Table : 1 pc

- Flat fixture : 1 pc

- Sheet specimen fixture : 1 pc

- Standard block of hardness : 2 pcs

- Spare fuse 2A : 2 pcs

- Horizontal adjusting screw : 4 pcs

- Power line : 1 pc

- Dust proof cover : 1 pc

- Manual Book : 1 pc

- Certificate of quality : 1 pc

- Screwdriver : 2 pcs

- Warranty Card : 1 pc

- Accessory box :1 pc

- Level bubble Note: For avoid potential risks, Will remove level bubble if ship by air, since liquid materials are forbidden by airlines : 1 pc

Software Description

Download Cataloge

ENQUIRY

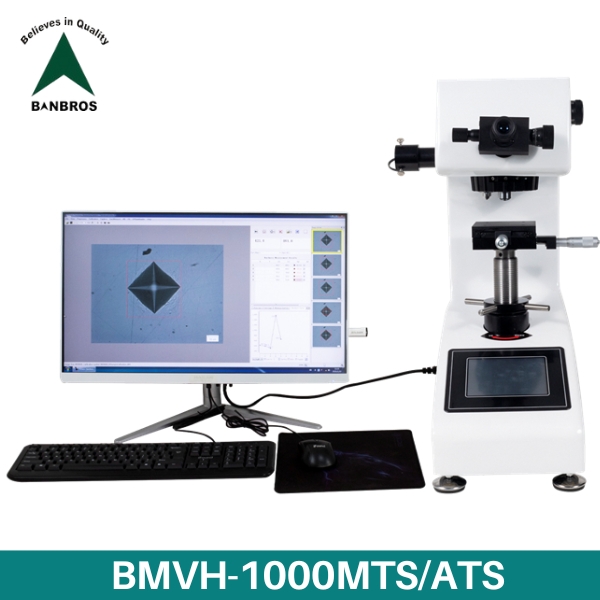

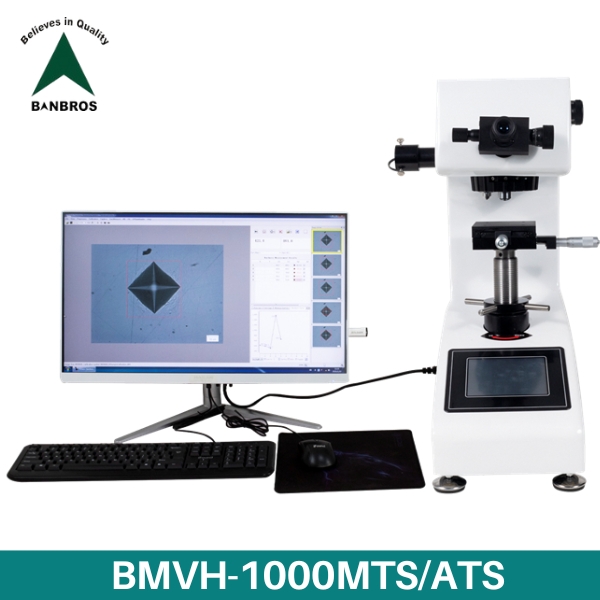

Digital Micro Vickers Hardness Tester With Touch Screen

Description

Application

- Steel, nonferrous metals, tinsel, cemented carbide, sheet metal, metallographic structure.

- Carburization, nitriding and decarburization layer, surface hardening layer, galvanized coating.

- Glass, chip and ceramic material.

Features

- Adopted one time casting aluminum machine body and car painting technology, structure more stable and appearance more decent.

- The independent research and development of lift & down system and positioning system, ensured the accuracy and repeatedly of the testing process.

- The optical system designed by our senior optical engineer not only meet the definition of hardness testing requirements, but also can observe the micro structure of the material, image is very clear.

- According to different visual habits of the operators, the strength of the light source can be adjusted. To avoid the visual fatigue for long time operation.

- With Vickers hardness and Knoop hardness testing capabilities. By measuring the indentation diagonal length, the hardness will show on the screen directly, no need to check hardness table.

- Industrial digital touch screen can direct display hardness value, conversion hardness value, testing method, testing force, dwell time, easy for operator to save the data.

- Double optical path design. Both eyepiece and CCD camera path can work at same time. No need switch optical path. Camera can be install inside machine (camera for optional purchase).

Specifications

| Model No. | BMVH-1000MTS | BMVH-1000ATS |

| Turret | Manual Turret | Automatic Turret |

| Testing force | 10g (0.098N), 25g (0.245N), 50g (0.49N), 100g (0.98N ), 200g (1.96N), 300g (2.94N), 500g (4.9N), 1000g (9.8N) Test force error: ±1.0% | |

| Hardness scale | HV0.01, HV0.025, HV0.05, HV0.1, HV0.2, HV0.3, HV0.5, HV1 | |

| Loading speed | ≤0.05mm/sec | |

| Indenter | Standard Rectangular pyramid diamond indenter (136º±0.5º) | |

| Min. measuring unit | 0.25μm | |

| Hardness value rang | 5HV-3000HV | |

| Data Display | 5.6’’ touch screen & Computer monitor software window | |

| Eyepiece | 10X manual analog eyepiece | |

| Objective lens | 10X (observe), 40X (Measurement) | |

| Total magnification | 100X (For Observation) , 400X (For Measurement) | |

| Loading method | Automatically (Load, dwell and unload the testing force) | |

| Duration time | 1-60s (each step is 1 second) | |

| Software System | Professional HV / HK hardness measurement software, can work with win10 computer system very well. Support automatic measurement & manual measurement, can generate test report in word / Excel format. | |

| Camera | 5 million pixel digital camera | |

| Maximum height | 90mm | |

| Throat depth | 95mm | |

| Instrument size and Net weight | 405*290*480mm (L×W×H) 40kg | |

| Packing size and Gross weight | 550x370x720mm( LxWxH) 56kg | |

| Light Source | LED cold light source | |

| Power Supply | 220V + 5%, 50/60 Hz (110V is available) | |

| X-Y Testing Table | Dim.:100×100 mm, Max. Travel Range: 25×25mm, Moving Resolution Ratio: 0.01mm | |

| Executed Standard | GB/T4340, ASTM E384 & E92, EN-ISO 6507, JIS B-7734 | |

Accessories

- Weights shaft :1 pc

- Weights : 6 pcs

- 10X manual micrometer eyepiece : 1 pc

- 10X objective lens : 1 pc

- 40X objective lens : 1 pc

- Vickers diamond indenter : 1 pc

- X-Y Testing Table : 1 pc

- Level bubble : 1 pc

- Flat fixture : 1 pc

- Sheet specimen fixture : 1 pc

- Standard block of hardness : 2 pcs

- Spare fuse 2A : 2 pcs

- Horizontal adjusting screw : 4 pcs

- Power line : 1 pc

- Dust proof cover : 1

- Manual Book, QC certificate : 1 pc

- Software system & camera : 1 pc

- Screwdriver : 2 pcs

- Warranty Card : 1 pc

- Accessory box : 1 pc

Software Description

Download Cataloge

ENQUIRY

Micro Vickers Hardness Tester With Software System

Description

Application

Features

- It’s equipped with Vickers, Knoop indenter and 4 kinds of objective lens.Vickers hardness and Knoop hardness values can be measured simultaneously.

- Adopt optical cross guide rail lifting mechanism, force value is accurate, the image is clear, is an ideal high-end micro hardness tester.

- Installed with Vickers, Knoop head and 4 objectives;

- During the test, the indenter and the objective lens automatically switch to each other, and the test point automatically locates accurately.

- Lifting mechanism guided by optical cross rail ensures guiding accuracy;Using rack and pinion two stage force transmission, can achieve fast and smooth force transmission;

- LED light source, long life, no need to replace the bulb;

- Equipped with built-in camera, the image is clearer;

- It can be calibrated according to standard hardness blocks or length scales, and the hardness can be corrected automatically according to high, medium and low hardness values, so that the hardness value is more accurate.

- 8 inch touch screen interface, easy to operate;

- Data statistics save, easy to query and print out;

- Various hardness values convert to each other;

- Test setting parameters are protected by password;

- At least 3 languages such as Chinese and English are available;

- Equipped with RS-232 interface for computer connection;

- Optional maximum test force 2kg.

Specifications

| Model No. | BHVS-1000TZ-IVD |

| Test force | 10GF (0.098N), 25GF (0.245N), 50GF (0.49N), 100GF (0.98N), 200GF (1.96N), 300GF (2.94N), 500GF (4.9N), 1Kgf (9.8N) |

| Meet standard | GB/T4340.2, GB/T 18449.2?ASTM E92 |

| Measurement resolution | 0.01μm |

| Data display output | 8-inch touch screen displays readings, stores 20 test results, has a built-in printer and RS-232 interface, and an optional USB flash drive |

| Conversion scale | Rockwell, Brinell |

| Hardness test range | 8 ~ 2900 HV/HK, |

| Test force application method | Automatic (loading, preserving, unloading) |

| Eyepiece magnification | 10X |

| Total magnification | 400X, 200X, 100X, 50X (test, observation) (500X optional) |

| Test force dwell time | 1-99s |

| Max. allowable specimen height | 100mm |

| Distance from indenter to wall | 130 mm |

| X-Y platform | Size: 100*100mm Maximum movement: 25*25mm |

| Size | 540*260*650mm |

| Weight | About 50 kg |

| Power supply | AC220V + 5%, 50 to 60 hz |

Accessories

| Item | Qt’y | Item | Qt’y |

| Weight shaft | 1 | Weight | 6 |

| Micrometer eyepiece (DHV-1000-10X) | 1 | Micro hardness block (high block, medium block) | Each 1 |

| X-Y table | 1 | Nylon universal sole | 4 |

| Level | 1 | Spare fuse (2A) | 2 |

| Power cord | 1 | Dust cover | 1 |

| Product certificate, warranty card | 1 | Instructions | 1 |

| Printing paper | 1 | Touch pen | 1 |

| Screwdriver | 2 |

Software Description

Download Cataloge

ENQUIRY

Auto Turret Touch Screen Digital Display Micro Hardness Tester

Description

BMVH-1XYZ Fully Automatic Micro Vickers Hardness Tester is integrated with several new technologies such as optical imaging, mechanical displacement, electronic control, digital imaging, image analysis, computer processing and so on. It controls the Micro Vickers hardness tester and automatic test table by the computer, and displays the indentation image on the computer screen. By means of automatic reading and manual reading, it accurately measures the HV hardness, hardening depth, film thickness, distance between two points of metals and some non-metallic materials and various films. It also can shoot metal surface morphology and taking fixed rate printing etc. This system breaks through the traditional test method, realize the hardness test of fully automatic, high precision, high repeatability, and it is the important equipment for materials analysis.

Application

Features

- Fully Automation: With click of a button, system starts automatic test and measurement process in indentation, auto-focusing, measuring, and hardness curve plotting;

- Motorized XY Sample Stage: System provides motorized XY sample stage, with XY stage table dimensions 110mmX110mm, travel lengths 50mmX50mm, and position precision 2 µm as standard. Can be controlled by joystick and by software. Table dimensions and travel lengths can be customized.

- Test Pattern and Path Setup: Sets up test paths with various patterns such as line, line set, arc, gear top parallel, gear center, and matrices etc.;

- Automatic Sample Boundary Scan: Automatically scans along the sample boundary to obtain the sample overview image which is necessary in many test cases to set up test load paths;

- Hardness curve, Statistics, Auto-alarm: Automatically detects and plots multiple hardness curves and calculates the hardness case depths. Automatically updates the statistics such as average, min and max, standard deviation, Cp, and Cpk; Automatically marks data that are out of specification limits; May load the depth template file for convenience.

- Conversion, compensation, and validation: Converts HV to other hardness scales, simultaneously; Validates the test results with sample dimensions; Compensates the test results with respect to sample cylindrical/spherical diameters;

- Data archiving: Measurement data and images can be saved in one file for later processing;

- Test report: Automatically generates WORD, EXCEL or PDF report with customizable template; May enter user additional information in report.

- Data output by network: Sends data to TCP/IP server in network to enterprise database.

- Knoop Scale, Fracture Toughness: Can be configured for Knoop Scale measurement; Also, for Fracture Toughness measurement by indentation;

- Other functionalities: Image/Video capture/save; Geometric measurements; Document entries, etc.;

- Stable Structure design: Adopted one time casting aluminum machine body and car painting technology, structure more stable and appearance more decent;

- Multi-functions: Support automatic measuring with computer and software, also support manual test by machine independently. Double optical path design. Both eyepiece and CCD camera path can work at same time. No need switches optical path;

Specifications

| Model No. | BMVH-1XYZ | |

| Test Force | gf | 10gf, 25gf, 50gf, 100gf, 200gf, 300gf, 500gf, 1000gf |

| N | 0.098N, 0.246N, 0.49N, 0.98N, 1.96N, 2.94N, 4.90N, 9.80N | |

| Test Range | 1HV-2967HV | |

| Test Mode | HV/HK | |

| Loading Method | Automatic (Loading/Dwell/Unloading) | |

| Turret | Automatic Shifting | |

| Conversion Scale | HK, HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRK, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HS, HB | |

| Data Output |

Built-in Printer; Computer screen (software window) WORD or EXCEL Report with Curve Chart |

|

| Hardness Reading | Indentation Displaying and Automatic Measuring on PC | |

| Objective | 10X (Observe), 40X (Measure) | |

| Eyepiece | Digital 10X eyepiece with built-in encoder, auto calculate | |

| Total Magnification | 100X, 400X | |

| Resolution | 0.0625μm, measuring range 200um | |

| Dwell Time | 5-99s, each step 1 second | |

| Machine display | Touch screen | |

| Light Source | LED cold light source (can be continuous use for 24 hours, no heat generates ensure stable working, servicing life can reach 100,000 hours) | |

| Max. Height of Specimen | 80mm | |

| Throat | 110mm | |

| Power Supply | AC220V,50Hz | |

| Execute Standard | ISO 6507, ASTM E384, JIS Z2244, GB/T 4340.2 | |

| Dimension | 215×450×468mm, Packing Dimension: 560×390×810mm | |

| Weight | Net Weight: 45kg, Gross Weight: 60kg | |

Accessories

| Item Name | Q’ty | Item Name | Q’ty |

| Professional Automatic Version HV Measuring Software | 1 | Flat fixture | 1 |

| Software USB Dongle | 1 | Sheet specimen fixture | 1 |

| Motorized Test Table Control Box | 1 | Standard block of hardness | 2 |

| Motorized X-Y Testing Table | 1 | Spare fuse 2A | 2 |

| Digital camera & camera adapter | 1 | Horizontal adjusting screw | 4 |

| Weights shaft | 1 | Power line | 1 |

| Weights | 6 | Dust proof cover | 1 |

| 10X digital eyepiece | 1 | Manual Book | 1 |

| 10X objective lens | 1 | Certificate of quality | 1 |

| 40X objective lens | 1 | Screwdriver | 2 |

| Vickers diamond indenter | 1 | Warranty Card | 1 |

|

|

Accessory box | 1 |

Software Description

Download Cataloge

ENQUIRY

Automatic Digital Micro Vickers Hardness Tester

Description

Application

- Heat treatment, carbide, quench hardened layer, the surface coating layer, steel, non-ferrous metal and small and thin shape parts, etc.

Features

- It is equipped with Vickers, Knoop indenter and high power (40X/50X) and low power objective lens (10X/20X) at the same time.

- During the test, the indenter and the objective lens automatically switch to each other, and the automatic positioning of the test point is accurate.

- The lifting mechanism with optical cross guide rail is adopted to ensure the guiding accuracy. Rack and pinion two stage force transmission, can realize fast and stable force transmission;

- Light source using LED lamp, long life, no need to replace the bulb.

- Can be equipped with a built-in camera, the image is clearer.

- It can be calibrated according to the standard hardness block or length scale, and it can automatically correct the hardness according to the high, middle and low hardness values, and the hardness values are more accurate.

- 8”touch screen interface, easy to operate.

- All test parameters and results are stored on USB flash disk in Excel format, which is convenient for data processing and test report output.

- Various hardness values are converted to each other.

- Test setting parameters are protected by password;

- At least 3 languages, including Chinese and English, are available.

- With RS-232 interface, can be connected with the computer.

- Adopt optical cross guide rail lifting mechanism, force value is accurate, the image is clear.

- Optional maximum test force 2kg.

Specifications

| Model No. | BHVS-1000TZ- IID |

| Test force | 10gf (0.098N), 25gf (0.245N), 50gf (0.49N), 100gf (0.98N), 200gf (1.96N), 300gf (2.94N), 500gf(4.9N), 1kgf (9.8N) |

| Standard Conformed to | GB/T 4340.2, GB/T 18449.2, ASTM E92 |

| Min measuring unit | 0.01µm |

| Conversion Scale | Rockwell, Brinell |

| Hardness measuring range | 8~2900HV |

|

Method of testing force applied |

Automatic (Loading, Dwelling, Unloading) |

| Turret Type | Automatic |

| Test microscope magnification | 400X(Measuring)?100X (test, observation) (Optional: 200X, 500X) |

| Test force dwell time | 1~99s |

| X-Y test sets | Dimension: 100*100mm Maximum travel 25*25mm |

| Data output | 8 " touch screen display reading, can store 20 kinds of test results, equipped with U disk, optional built-in printer and RS-232 interface |

| Maximum specimen height | 100mm |

| Distance from the center to the outer wall of the indenter | 130mm |

| Power supply | AC 220V or 110V, 50 or 60Hz |

| Dimensions | 540*260*650mm |

| Net Weight | About 50Kg |

Accessories

| Item | Qt’y | Item | Qt’y |

| Weight shaft | 1 | Weight | 6 |

| Micrometer eyepiece?10X? | 1 | X-Y table | 1 |

|

Vickers hardness block (high block, middle block) |

1 each | Touch pen | 1 |

| Level | 1 | Plastic dust cover | 1 |

| Hexagon wrench (2.5mm) | 1 | Nylon universal sole(Adjusting screw) | 4 pcs. |

| Power line | 1 | Spare fuse (2A) | 2 pcs. |

| Printing paper | 1 |

Software Description

Download Cataloge

ENQUIRY

Auto Turret Touch Screen Micro Hardness Tester

Description

Application

- Heat treatment, carbide, quench hardened layer, the surface coating layer, steel, non-ferrous metal and small and thin shape parts, etc.

Features

1. Installed with Vickers indenter and 3 objectives;

2. During the test, the indenter and the objective lens automatically switch to each other, and the test point automatically locates accurately.

3. Lifting mechanism guided by optical cross rail ensures guiding accuracy;Using rack and pinion two stage force transmission, can achieve fast and smooth force transmission;

4. LED light source, long life, no need to replace the bulb;

5. Equipped with built-in camera, the image is clearer;

6. It can be calibrated according to standard hardness blocks or length scales, and the hardness can be corrected automatically according to high, medium and low hardness values, so that the hardness value is more accurate.

7. 8 inch touch screen interface, easy to operate;

8. Data statistics save, easy to query and print out;

9. Various hardness values convert to each other;

10. Test setting parameters are protected by password;

11. At least 3 languages such as Chinese and English are available;

12. Equipped with RS-232 interface for computer connection;

13. Optional maximum test force 2kg.

Specifications

| Model No. | BHVS-1000TZ-IIIS |

| Test force | 10gf (0.098N), 25gf (0.245N), 50gf (0.49N), 100gf (0.98N), 200gf (1.96N), 300gf (2.94N), 500gf(4.9N), 1kgf (9.8N) |

| Standard Conformed to | GB/T 4340.2, ISO 6507-2, ASTM E384 |

| Min measuring unit | 0.01µm |

| Conversion Scale | Rockwell, Brinell |

| Hardness measuring range | 8~2900HV |

| Data output | 8-inch touch screen displays readings, stores 20 test results, has a built-in printer and RS-232 interface, and an optional USB flash drive |

|

Method of testing force applied |

Automatic (Loading, Dwelling, Unloading) |

| Turret Type | Automatic |

| Magnification of eyepiece | 10X |

| Magnification of objective lens | Choose three from 40X, 20X, 10X, 5X (test, observation) (50X optional) |

| Test force dwell time | 1~99s |

| X-Y test sets | Dimension: 100*100mm Maximum travel 25*25mm |

| Maximum specimen height | 100mm |

| Distance from the center to the outer wall of the indenter | 130mm |

| Power supply | AC 220V or 110V, 50 or 60Hz |

| Dimensions | 540*260*650mm |

| Net Weight | About 50Kg |

Accessories

| Item | Qt’y | Item | Qt’y |

| Weight shaft | 1 | Weight | 6 |

| Micrometer eyepiece | 1 | Microhardness block (high block, medium block) | 1 each |

| X-Y table | 1 | Nylon universal sole | 4 |

| Level | 1 | Spare fuse (2A) | 2 |

| Power cord | 1 | Dust cover | 1 |

| Product certificate, warranty card | 1 | Instructions | 1 |

| Printing paper | 1 | Touch pen | 1 |

| Screwdriver | 2 |

Software Description

Download Cataloge

ENQUIRY

Auto Turret Touch Screen Digital Display Microhardness Tester

Description

Application

- Heat treatment, carbide, quench hardened layer, the surface coating layer, steel, non-ferrous metal and small and thin shape parts, etc.

Features

- Automatic turret shifting between indenter and objective lens

- Standard 8-level force, from 10gf (0.098N) to 1kgf (9.8N), 2Kgf (19.6N) is optional, users can customize the test force.

- After measuring the indentation diagonal length, the system will automatically calculate and display the hardness value.

- Both two objectives can be used to test hardness value.

- Based on the standard block of different forces, the hardness value can be corrected automatically.

- 8” Touch-screen interface, easy to operate, multi-language is available.

- Testing data can be saved into U disk directly in EXCEL format, which is convenient for easy editing and processing.

- The information of test samples, operator etc. can be input and saved.

- Password can be set to protect setting parameters.

- Measured hardness value can be automatically converted to other scales.

- Modular design, easy maintenance, large space for sample.

- Optional image measuring system can be equipped with this hardness tester so as to connect with computer for automatic operation.

Specifications

| Model No. | BHVS-1000TZ |

| Test force |

10gf (0.098N), 25gf (0.245N), 50gf (0.49N), 100gf(0.98N), 200gf (1.96N), 300gf (2.94N), 500gf(4.9N), 1kgf (9.8N) |

| Standard Conformed to | GB/T 4340.2, ISO 6507-2, ASTM E384 |

| Min measuring unit | 0.01µm |

| Conversion Scale | HRA, HRB, HRC, HRD, HRF, HV, HK, HBW, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T |

| Hardness measuring range | 8~2900HV |

|

Method of testing force applied |

Automatic (Loading, Dwelling, Unloading) |

| Turret Type | Automatic |

| Test microscope magnification | 400X(Measuring),100X (observation) (Optional 50X, 200X, 500X, Maximum 1000X) |

| Test force dwell time | 1~99s |

| X-Y test sets | Dimension: 100*100mm Maximum travel 25*25mm |

| Data output | Touch-screen display, RS232 interface & Printer. USB disk interface is optional to replace printer |

| Maximum specimen height | 100mm |

| Distance from the center to the outer wall of the indenter | 135mm |

| Power supply | AC 220V or 110V, 50 or 60Hz |

| Dimensions | 540*260*650mm |

| Net Weight | About : 50Kg |

Accessories

| Item | Qt’y | Item | Qt’y |

| Axle weight | 1 | Weight | 6 |

| Cross test sets | 1 | 10X eyepiece test | 1 |

|

Vickers hardness block (high block, middle block) |

1 each | USB disk (Optional) | 1 |

| Level | 1 | Plastic dust cover | 1 |

| Screwdriver | 2 | Adjusting screw | 4 pcs. |

| Power line | 1 | Spare fuse (2A) | 2 pcs. |

| Product Manual | 1 | Product certification | 1 |

Software Description

Download Cataloge

ENQUIRY

Auto Turret Touch Screen Digital Display Microhardness Tester

Description

Application

- Heat treatment, carbide, quench hardened layer, the surface coating layer, steel, non-ferrous metal and small and thin shape parts, etc.

Features

- Simplified version without printer and interface, single lens for measurement.

- Manual turret shifting between indenter and objective lens

- Standard 8-level force, from 10gf (0.098N) to 1kgf (9.8N), 2Kgf (19.6N) is optional, users can customize the test force.

- After measuring the indentation diagonal length, the system will automatically calculate and display the hardness value.

- Based on the standard block of different forces, the hardness value can be corrected automatically.

- ” Touch-screen interface, easy to operate, multi-language is available.

- esting data can be saved into U disk directly in EXCEL format, which is convenient for easy editing and processing (Optional USB interface).

- The information of test samples, operator etc. can be input and saved.

- Password can be set to protect setting parameters.

- Measured hardness value can be automatically converted to other scales.

- Modular design, easy maintenance, large space for sample.

- Optional image measuring system can be equipped with this hardness tester so as to connect with computer for automatic operation.

Specifications

| Model No. | BHVS-1000TS |

| Test force | 10gf (0.098N), 25gf (0.245N), 50gf (0.49N), 100gf (0.98N), 200gf (1.96N), 300gf (2.94N), 500gf(4.9N), 1kgf (9.8N) |

| Standard Conformed to | GB/T 4340.2, ISO 6507-2, ASTM E384 |

| Min measuring unit | 0.01µm |

| Conversion Scale | 8~2900HV |

| Hardness measuring range | 8~2900HV |

| Method of testing force applied | Automatic (Loading, Dwelling, Unloading) |

| Turret Type | Manual |

| Test microscope magnification |

400X (Measuring),100X (observation) (Optional 50X, 200X, 500X, Maximum 1000X) |

| Test force dwell time | 1~99s |

| X-Y test sets | Dimension: 100*100mm Maximum travel 25*25mm |

| Data output | Touch-screen display, RS232 interface & Printer. USB disk interface is optional to replace printer |

| Maximum specimen height | 100mm |

| Distance from the center to the outer wall of the indenter | 135mm |

| Power supply | AC 220V or 110V, 50 or 60Hz |

| Dimensions | 540*260*650mm |

| Net Weight | About 50Kg |

Accessories

| Item | Qt’y | Item | Qt’y |

| Axle weight | 1 | Weight | 6 |

| Cross test sets | 1 | 10X eyepiece test | 1 |

|

Vickers hardness block (high block, low block) |

1 each | USB disk (Optional) | 1 |

| Level | 1 | Plastic dust cover | 1 |

| Screwdriver | 2 | Adjusting screw | 4 Pcs. |

| Power line | 1 | Spare fuse (2A) | 2 pcs. |

| Product Manual | 1 | Product certification | 1 |

Software Description

Download Cataloge

ENQUIRY

Touch Screen Digital Display Micro Vickers Hardness Tester

Description

Application

- Heat treatment, carbide, quench hardened layer, the surface coating layer, steel, non-ferrous metal and small and thin shape parts, etc.

Features

- Manual turret shifti ng between indenter and objective lens

- Standard 8-level force, from 10gf (0.098N) to 1kgf (9.8N), 2Kgf (19.6N) is optional, users can customize the test force.

- After measuring the indentation diagonal length, the system will automatically calculate and display the hardness value.

- Both two objectives can be used to test hardness value.

- Based on the standard block of different forces, the hardness value can be corrected automatically.

- 8” Touch-screen interface, easy to operate, multi-language is available.

- Testing data can be saved into U disk directly in EXCEL format, which is convenient for easy editing and processing (Optional USB interface).

- The information of test samples, operator etc. can be input and saved.

- Password can be set to protect setting parameters.

- Measured hardness value can be automatically converted to other scales.

- Modular design, easy maintenance, large space for sample.

- Optional image measuring system can be equipped with this hardness tester so as to connect with computer for automatic operation.

Specifications

| Model No. | BHVS-1000BT |

| Test force | 10gf (0.098N), 25gf (0.245N), 50gf (0.49N), 100gf (0.98N), 200gf (1.96N), 300gf (2.94N), 500gf(4.9N), 1kgf (9.8N) |

| Standard Conformed to | GB/T 4340.2, ISO 6507-2, ASTM E384 |

| Min measuring unit | 0.01µm |

| Conversion Scale | HRA, HRB, HRC, HRD, HRF, HV, HK, HBW, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T |

| Hardness measuring range | 8~2900HV |

| Method of testing force applied | Automatic (Loading, Dwelling, Unloading) |

| Turret Type | Manual |

| Test microscope magnification | 400X(Measuring),100X (observation) (Optional 50X, 200X, 500X, Maximum 1000X) |

| Test force dwell time | 1~99s |

| X-Y test sets | Dimension: 100*100mm Maximum travel 25*25mm |

| Data output | Touch-screen display, RS232 interface & Printer. USB disk interface is optional to replace printer |

| Maximum specimen height | 100mm |

| Distance from the center to the outer wall of the indenter | 135mm |

| Power supply | AC 220V or 110V, 50 or 60Hz |

| Dimensions | 540*260*650mm |

| Net Weight | About 50Kg |

Accessories

| Item | Qt’y | Item | Qt’y |

| Axle weight | 1 | Weight | 6 |

| Cross test sets | 1 | 10X eyepiece test | 1 |

|

Vickers hardness block (high block, low block) |

1 each | USB disk (Optional) | 1 |

| Level | 1 | Plastic dust cover | 1 |

| Screwdriver | 2 | Adjusting screw | 4 each |

| Power line | 1 | Spare fuse (2A) | 2each |

| Product Manual | 1 | Product certification | 1 |

Software Description

Download Cataloge

ENQUIRY

Digital Display Touch Screen Micro Vickers Hardness Tester

Description

Application

Heat treatment, carbide, quench hardened layer, the surface coating layer, steel, non-ferrous metal and small and thin shape parts, etc.

Features

- BHVS-1000Z adopts touch screen display,, convenient for users to choose; The operation interface adopts menu-type structure. Hardness scale HV or HK can be selected on the operation panel. During the test, the pressure head and objective lens automatically switch with each other, and the test point is automatically positioned accurately; Various hardness values can be converted to each other; The brightness of the light source can be adjusted.

- The optical cross guide rail is adopted to ensure the guiding accuracy; The speed and stability of transmission can be realized by using the two-stage pinion and rack transmission. High trBHansmission ratio high precision worm gear worm, ensure more accurate transmission force.

- Can be equipped with a built-in camera, the image is clearer

- Can be calibrated according to the standard hardness block or length scale, so that the hardness value more accurate in line with the requirements.

- Eyepiece structure with digital encoder, and the touch screen directly displays the hardness value and D1 and D2 values.

- With automatic turret structure, the indenter objective lens can be switched automatically.

Specifications

| Model No. | BHVS-1000Z |

| Test force |

10gf (0.098N), 25gf (0.245N), 50gf (0.49N), 100gf(0.98N), 200gf (1.96N), 300gf (2.94N), 500gf(4.9N), 1kgf (9.8N) |

| Standard Conformed to | GB/T 4340.2, ISO 6507-2, ASTM E92 |

| Min measuring unit | 0.01µm |

| Conversion Scale | Rockwell, Brinell |

| Hardness measuring range | 8~2900HV |

|

Method of testing force applied |

Automatic (Loading, Dwelling, Unloading) |

| Turret Type | Automatic |

| Test microscope magnification | 400X(Measuring),100X (observation) |

| Test force dwell time | 1~99s |

| X-Y test sets | Dimension: 100*100mm Maximum travel 25*25mm |

| Data display output | 8” Touch-screen display, can store 20 kinds of test results |

| Maximum specimen height | 100mm |

| Distance from the center to the outer wall of the indenter | 130mm |

| Power supply | AC 220V or 110V, 50 or 60Hz |

| Dimensions | 540*260*650mm |

| Net Weight | About 50Kg |

Accessories

| Item | Qt’y | Item | Qt’y |

| Weight shaft | 1 | Weight | 6 |

| Micrometer eyepiece | 1 | X-Y table | 1 |

|

Vickers hardness block (high block, middle block) |

1 Each |

Nylon universal sole (Adjusting screw) |

4 |

| Level | 1 | Plastic dust cover | 1 |

| Screwdriver | 2 | Touch pen | 1 |

| Power line | 1 | pare fuse (2A) | 2 |

| Hexagon wrench (2.5mm) | 1 |

Software Description

Download Cataloge

ENQUIRY

Auto Turret Touch Screen Hardness Tester

Description

Application

Features

- This measuring system can be equipped with various kinds of Vickers Hardness Tester to upgrade unit tester to measuring system;

- The computer controls the hardness tester, such as turret, light illumination adjustment (only can be equipped with BHVS- Z series);

- It is applicable to Micro Vickers and Vickers with max. testing forces to 1, 5, 10, 30, 50Kgf;

- With clear image, indentation measurement by automatic or manual;

- Digital X axis movement value can be input into program and generate hardened layer depth distribution curve automatically;

- Calibration by micrometer or test block, can be automatically calibrated;

- Hardness conforms to ASTM standard to convert to other hardness scales, with hardness value statistics and sound alarm beyond limitation;

- Testing report can be customized as per user’s requirement, all the testing data can be saved permanently, easy to check.

- The image is clear, automatic / manual measurement of the indentation size;

- The digital sample position, automatically entered into the computer

- Automatic generation of hardness layer depth profile

- Calibration using micrometer or hardness block calibration, automatic calibration;

- Hardness by GB and ASTM converted to other hardness; statistical Hardness Value exceed alarm;

- Customized test reports, all test data is always saved for easy historical inquiry.

- The program automatically calculates the hardness profile along the depth and effective case depth

- X, Y Axis Location Digital Accuracy: 1μm

- X axis location value can enter into hardness measuring program directly, the program calculate the hardness value along depth distribution curve and effective hardened layer depth automatically.

Specifications

Accessories

Software Description

- Camera 5.0M pixel: 1 pc.

- Interface tube: 1 pc.

- U-disk containing the software and manuals: 1 pc.

- Dongle: 1 pc.

- Digital X-Y Stage: 1 pc.

- Digital accuracy of X & Y axis: 1μm.

- The position of X axis can enter into the hardness measuring program directly, and the program can automatically calculate hardness along depth distribution curve and effective hardened layer depth.

Download Cataloge

ENQUIRY

Vickers Ccd Image Measuring & Controlling System

Description

Application

Features

- This system can match a variety of Vickers hardness testers to upgrade unit hardness tester to computer measuring system.

- This measuring system can be integrated with the hardness testers BHVS- Z series; computer-controlled for auto turret and brightness adjustment etc.

- Suitable for micro and Vickers hardness tester, the maximum test force can be 1, 5, 10, 30, 50Kg.

- Image with high resolution and indentation measurement by auto or manual;

- Digital X-axis value, and automatically enter the program automatically generates the deep layer of hardness distribution curve (optional);

- Calibration using micrometer or hardness block, can be calibrated automatically;

- Hardness converted to other hardness scales according to ASTM standard.

- Statistics for hardness values and alarm for hardness values out of range;

- Easy to install, use laptops instead of desktop computers;

- Interface is simple and easy to use without training;

- Test reports can be customized; all testing data can be saved for long time and easy for historical inquiry.

- Digital camera with 1280*1080 pixels, 1/2-inch, USB 2.0

Specifications

Accessories

- Digital X-Y Stage 1 pc.

- Digital accuracy of X & Y axis: 1μm.

- The position of X axis can enter into the hardness measuring program directly, and the program can automatically calculate hardness along depth distribution curve and effective hardened layer depth.

- Lenovo Computer 1 pc.

Software Description

Download Cataloge

ENQUIRY

Vickers Ccd Image Measuring System

Description

- Manual turret shifting between indenter and objective lens.

- Large 8” touch screen, direct visual display and interactive operating interface.

- High speed ARM processor, fast operation speed and extensive database storage.

- High quality integral casting cast iron machine body with automotive paint treatment process, the appearance is smooth and beautiful.

- The hardness scale, test force, indenter type, holding time and the conversion unit can be displayed on screen and set.

- The turbo-worm elevating system can greatly improve the testing stability and accuracy.

- HD measurement and observation - dual objective lens combination, combined with the built-in length encoder HD micrometer eyepiece, to achieve indentation diagonal one-key measurement, greatly reduce the manual interference and reading error.

- Convenient control system can automatically convert the unit of full hardness scales.

- The maximum and minimum hardness values can be set, when the test value exceeds the set range, an alarm sound will be issued.

- With the function of software hardness value correction, the hardness value can be directly corrected within a certain range.

- With the database function, the testing data can be saved automatically in groups, each group can save 10 data, totally can save up to 2000 data.

- With the hardness value curve display function, intuitively display the changes of hardness value.

- CCD image measuring system is optional.

- Knoop indenter can be selected to measure the Knoop hardness.

- Equipped with wireless blue-tooth printer, the data can be output through RS232 or USB interface.

- Precision conforms to GB/T4340.2, ISO6507-2 and ASTM E384.

- It can be used to determine the Vickers hardness of steel, non-ferrous metals, ceramics, treated layers of metal surface, and the hardness grads of carburized, nitrided and hardened layers of metals. It is also suitable to determine the Vickers hardness of micro and super thin parts.

Application

Features

- Manual turret shifting between indenter and objective lens.

- Large 8” touch screen, direct visual display and interactive operating interface.

- High speed ARM processor, fast operation speed and extensive database storage.

- High quality integral casting cast iron machine body with automotive paint treatment process, the appearance is smooth and beautiful.

- The hardness scale, test force, indenter type, holding time and the conversion unit can be displayed on screen and set.

- The turbo-worm elevating system can greatly improve the testing stability and accuracy.

- HD measurement and observation - dual objective lens combination, combined with the built-in length encoder HD micrometer eyepiece, to achieve indentation diagonal one-key measurement, greatly reduce the manual interference and reading error.

- Convenient control system can automatically convert the unit of full hardness scales.

- The maximum and minimum hardness values can be set, when the test value exceeds the set range, an alarm sound will be issued.

- With the function of software hardness value correction, the hardness value can be directly corrected within a certain range.

- With the database function, the testing data can be saved automatically in groups, each group can save 10 data, totally can save up to 2000 data.

- With the hardness value curve display function, intuitively display the changes of hardness value.

- CCD image measuring system is optional.

- Knoop indenter can be selected to measure the Knoop hardness.

- Equipped with wireless blue-tooth printer, the data can be output through RS232 or USB interface.

- Precision conforms to GB/T4340.2, ISO6507-2 and ASTM E384.

- It can be used to determine the Vickers hardness of steel, non-ferrous metals, ceramics, treated layers of metal surface, and the hardness grads of carburized, nitrided and hardened layers of metals. It is also suitable to determine the Vickers hardness of micro and super thin parts.

Specifications

| Model No. | BHVS-1000T |

| Test force | 10, 25, 50, 100, 200, 300, 500, 1000gf (0.09807, 0.2452, 0.4904, 0.9807, 1.961, 2.942, 4.904, 9.807N) |

| Conversion Scale | HRA, HRB, HRC, HRD, HRE, HRF, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HB, HV, HS |

| Hardness measuring range | 5~5000HV |

| Measuring resolution | 0.025µm |

| Hardness resolution | 0.1HV |

| Max Height of Specimen | 120mm |

| Depth of throat | 110mm |

| X-Y Testing table |

Dimension: 100*100mm Max. travel: 25*25mm grade division of micrometer head: 0.01mm |

| Carried standards | GBT4340.2, ISO6507-2, ASTM E384 |

| Magnification of eyepiece | 10X |

| Magnification of objective lens | 10X, 40X |

| Total magnification | 100X, 400X |

| Data output | LCD display, wireless blue-tooth printer, RS232 and USB interface |

| Dwelling time | 1~99s |

| Power supply | AC 220V or 110V, 50 or 60Hz |

| Overall Dimensions | 530*290*490mm |

| Net weight | About 45Kg |

Accessories

- X-Y Coordinate test anvil: 1 pc.

- Thin shaft anvil: 1 pc.

- Thin plate anvil: 1 pc.

- Flat nose pliers: 1 pc.

- Large V-notch anvil: 1 pc.

- Small V-notch anvil: 1 pc.

- Diamond pyramid penetrator: 1 pc.

- Micro-Vickers standardized block: 2 pcs.

Software Description

Download Cataloge

ENQUIRY

Touch Screen Digital Display Micro Vickers Hardness Tester

Description

Application

Features