- Home

- Products

- Hardness Tester

- Rockwell Hardness Tester

Description

BHR Series portable Rockwell hardness tester complies with the basic designing principles of Rockwell hardness testing in accordance with international standard ISO6508, American Standard ASTM E18 and ASTM E110.

The hardness values can be read directly from the Rockwell hardness testers after rapid and accurate operations. It can be considered as a non-destructive testing with very small indentations. This kind of testers can be used at site to test the finished or semi-finished work pieces piece by piece in batches. Rockwell hardness testers are mostly applied in the metal-processing enterprises.

Application

Common metal including iron and steel, Cu,Al,Ni,Ti,Pb, carburized layer and hard alloy, etc.

Features

- Small and Light :The tester is small and light. Its min weight is only 0.8kg.

- Simple Operation: Operation as simple as micro-meter.

- Convenient: Used on table or take out.

- High Reliability: Designed by Rockwell hardness test method

- High Accuracy: As accurate as desk testers. Complying with ISO6508 and ASTM E18.

- Traceable Test Block: Standard package including three standard Rockwell hardness blocks.

- Indenter: Certificated indenter by standard Rockwell hardness tester.

Specifications

| Model No. | BHR-1 |

| Initial Test Force | 10kgf |

| Total Test Force | 60 kgf, 100 kgf, 150 kgf |

| Test Resolution | 0.5 HR |

| Test Range | HRA,HRB,...HRV etc,15 scales. |

| Test head | 120°diamond cone indenter, 1.5 88mm hard alloy ball |

| Indication error | Complying with ISO 6508 and ASTM E18 |

| Repeatability error | Complying with ISO 6508 and ASTM E18 |

Accessories

Software Description

Download Cataloge

ENQUIRY

Portable Rockwell Hardness tester

Description

Portable Magnetic Digital Brinell and Rockwell hardness tester, which can make accurate Brinell hardness test with conventional indentation method of ISO 6506.2 and ASTM E 10.

It can also make rapid Brinell hardness test with depth-measuring method of ASTM E 103, and read hardness value directly. At the same time it also can do Rockwell hardness test according to Rockwell hardness testing method in ISO 6508.2 and ASTM E 18.

These functions can meet the demand of precise and rapid Brinell hardness testing on-site of large steel and iron parts.

It Simplified operation of Rockwell hardness and depth-measuring Brinell hardness, only need to load the total test force remain for several seconds and then unload the total test force to finish the test, it is very simple and high efficiency.

This instrument stores an accurate basic hardness, that is depth curve made from plenty hardness blocks; it also stores several Brinell curves of common materials. We can supply the service of making precise Brinell curve of common material according to customers’ requirement. Advanced curve correction methods can be used to test a variety of special materials.

This instrument can check and calibrate the accuracy on-site by precise indentation method at any time.

Application

- By means of magnetic attraction force, the tester can be mounted on the steel part to be tested. Its Brinell Hardness Test method and test conditions meet the requirement of standards ASTM E110 and ISO6506-2.

- Designed for rapid and accurate Brinell hardness test in the field , in combination with the MS-1 Brinell Indentation measurement system.

- Suitable for large or heavy steel parts that cannot be tested with bench hardness tester .

- Suitable for steel plates, steel pipes, mould, dies and other heat treated parts.

- Suitable for testing welding lines of boilers, pressure, vessels and pressure pipes.

- Alternative for Leeb Hardness Testers with lower accuracy and reliability.

Features

- World initial patent product

- With advanced imported sensors as well as high integration, high stability electronic components to keep the high reliability of the hardness tester.

- One hardness tester with Brinell and Rockwell two functions can meet the demands of most manufacturing users.

- It can make rapid Brinell hardness test with depth-measuring method of ASTM E 103, and read hardness value directly.

- Insensitive to temperature changing on workshop.

- Test by absorbing to iron and steel parts, and it can finish the test by unilaterally touching the parts. It can test any dimension parts, especially steel tubes and weld on pipes.

- Portable and easy to carry. The Total weight 5.3kg of the tester, it is the smallest Magnetic Digital Brinell and Rockwell hardness tester so far.

- Standard package including standard Brinell hardness test block and Rockwell hardness test block.

Specifications

| Model No. | BHR-200 |

| Initial Test Force | 10kgf |

| Total Test Force | 60 kgf, 100 kgf, 150 kgf |

| Test Resolution | 0.1 HR |

| Test Range | 20~88 HRA, 20~100 HRB, 20~70 HRC |

| Indication Error | Comply with ISO 6508 and ASTM E18 standards |

| Repeatability Error | Comply with ISO 6508 and ASTM E18 standards |

| Test Force Error | ≤ ± 1% |

| Operating Temperature | 0 ~50°C |

| Dimension | Flat : Area ≥ 195mm x 60 mm, Thickness : ≥ 5 mm |

| Cylinder | Diameter : ≥ 60 mm Length ≥ 200 mm, Thickness : ≥ 8 mm |

Accessories

- Main Instrument/ Tester

- Diamond Indenter

- Ball Indenter

- Brinell Hardness Block

- Rockwell Hardness Block

- Iron Seat

- Recharger

- Battery Box

Software Description

Download Cataloge

ENQUIRY

Digital Magnetic Rockwell Hardness Tester

Description

Fix Rockwell test head to the surface of iron and steel parts to test the hardness by applying magnetic force. Follow Rockwell hardness test method completely and the test condition complies with standard of ISO 6508 and ASTM E 18.

The magnetic Rockwell hardness tester is mainly applied in on-site quick test body hardness of steel parts.

Test hardness of steel plate, pipe, axis, mould, huge forgings and huge and medium-size heat treatment parts if surface available.

Test hardness of weld joint in boiler, pressure vessels, and pressure pipes.

Replace low accurate and reliable Leeb hardness testers.

Application

Features

• Convenient to Use : Attach to one side of part to test, no need to move it.

• NDT Testing : Quick, convenient, no damage test.

• Reading Scale : Similar reading system as micrometers, easy to read, and good repeatability.

• High Accuracy : Rather high accuracy, complying with ISO6508 and ASTM E18.

Specifications

| Model No. | BHR-100 |

| Initial Test Force for Rockwell | 10kgf |

| Total Test Force | 60kgf, 100kgf, 150kgf |

| Test head | 120°diamond indenter, 1.588mm carbide, ball indenter |

| Indication Error | Comply with ISO 6508 and ASTM E 18 |

| Indication Error | Comply with ISO 6508 and ASTM E 18 |

| Testing Resolution | 0.5 HR |

| Weight | 4.7 Kg |

| Surface : Flat | Area ≥ 180 mm x 60 mm, Thickness: ≥ 5 mm |

| Cylinder | Diameter ≥ 60 mm Length ≥ 200 mm, Thickness ≥ 8 mm |

Accessories

• Tester

• Diamond Cone Indenter

• Carbide Ball Indenter

• Standard Hardness Block

• Adapter

• Seat Iron

Software Description

Download Cataloge

ENQUIRY

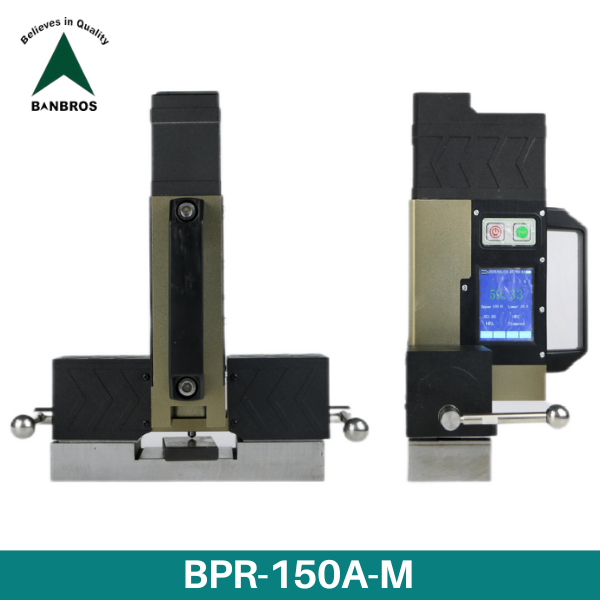

Magnetic Rockwell Hardness Tester

Description

Fully automatic hardness tester for efficient and repeatable measurements. Hardness testing is a fundamental requirement in materials science and industrial quality control, directly impacting a material's wear resistance, strength, and service life. The BPR-150A-M Magnetic Hardness Testers by BANBROS offer a compact, reliable, and portable solution for on-site hardness testing of steel, pipelines, bars, plates, and irregularly shaped components.

Unlike traditional Bench-top Hardness Testers, the BPR-150A-M uses a magnetic base to attach securely to ferrous materials, allowing for precise Rockwell hardness testing without the need for heavy or immobile equipment.

Application

This machine is used for finished and semi-finished parts of common metals, including steel, copper, aluminium, carburised layers, hard alloys, etc. It can also be used for the hardness of large plates, shafts, steel tubes, weldments and other combinations.

- Large forgings (e.g. rolls, bearing housings) body hardness test.

- Mould steel heat treatment effect assessment.

- Weld hardness testing of ship structural parts.

- Wind power equipment spindle hardness verification, etc.

Features

- This machine adopted modular design, machine test head can freely to combined with magnetic base or benchtop base or any other customized test table. Can meet more widely range materials’ Rockwell hardness test and makes hardness test work more easier.

- Fully automatic, automatic loading - dwell - unloading. For Rockwell test just press one key can get result directly, then can use Rockwell indentation measuring microscope to do measure work and get Rockwell hardness data (or measure by Rockwell indentation software, automatic measure to get data more easier and faster).

- Machine adopted high accuracy load cell and depth measuring system, ensure test result more accuracy.

- The machine adopts double handles plus magnetic switch, easy to operate, convenient to fix.

- With hardness conversion functions, freely convert to HV, HR, HBW, etc.

- Equipped with USB port, can save data to USB drive or through blue-tooth printer to print test data.

- The equipment adopts magnetic adsorption technology, combined with high-precision sensors and intelligent calibration system, to achieve fast, accurate and non-destructive hardness testing, especially suitable for on-site, on-line and complex working conditions hardness testing scenarios.

Specifications

| Model No. | BPR-150A-M |

| Version | Rockwell test with Magnetic base |

| Initial Test Force | 10kgf (98.07N) |

| Main Test Force | 60kgf(588.4N), 100kgf(980.7N), 150kgf (1471N) |

| Hardness Scale | HRA, HRB, HRC |

| Test Range | 20-95HRA, 10-100HRB, 20-70HRC |

| Indenter | 120? Rockwell diamond indenter, Ø1.5875mm Carbide Ball indenter |

| orce Control | Close loop load cell |

| Loading | Automatic loading - dwell - unloading test force |

| Data Transfer | Blue-tooth printer, USB port |

| Data Storage | 1000 pieces test data |

| Battery | Rechargeable lithium battery, Battery work continuous time 6 hours, Battery Charging Time 2 Hours |

| Machine Size /G.W | 208*115*267mm |

Accessories

- Machine Body: 1pc

- Magnetic Base: 1pc

- Diamond Indenter: 1pc

- 1.5875mm Carbide Ball Indenter: 1pc

- Hardness Block: 1pc

- Battery Charger: 1pc

Software Description

Download Cataloge

ENQUIRY

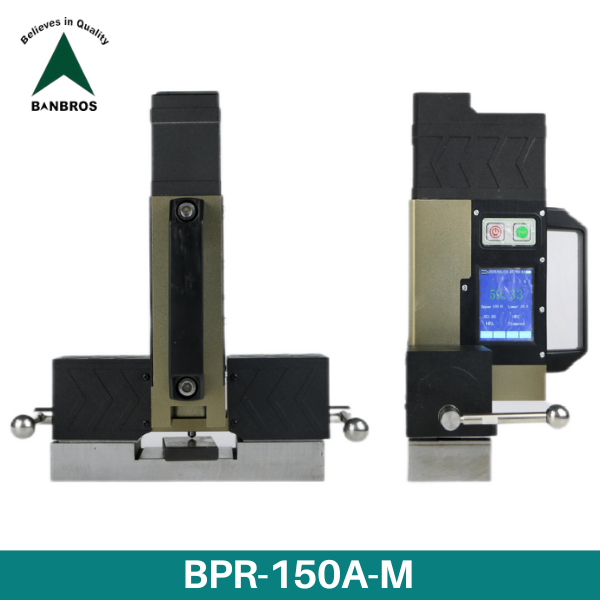

Automatic Portable Rockwell Hardness Tester

Description

Fully automatic hardness tester for efficient and repeatable measurements. Hardness testing is a fundamental requirement in materials science and industrial quality control, directly impacting a material's wear resistance, strength, and service life. The BPR-150A-M Magnetic Hardness Testers by BANBROS offer a compact, reliable, and portable solution for on-site hardness testing of steel, pipelines, bars, plates, and irregularly shaped components.

Unlike traditional Bench-top Hardness Testers, the BPR-150A-M uses a magnetic base to attach securely to ferrous materials, allowing for precise Rockwell hardness testing without the need for heavy or immobile equipment.

Application

This machine is used for finished and semi-finished parts of common metals, including steel, copper, aluminium, carburised layers, hard alloys, etc. It can also be used for the hardness of large plates, shafts, steel tubes, weldments and other combinations.

- Large forgings (e.g. rolls, bearing housings) body hardness test.

- Mould steel heat treatment effect assessment.

- Weld hardness testing of ship structural parts.

- Wind power equipment spindle hardness verification, etc.

Features

- This machine adopted modular design, machine test head can freely to combined with magnetic base or benchtop base or any other customized test table. Can meet more widely range materials’ Rockwell hardness test and makes hardness test work more easier.

- Fully automatic, automatic loading - dwell - unloading. For Rockwell test just press one key can get result directly, then can use Rockwell indentation measuring microscope to do measure work and get Rockwell hardness data (or measure by Rockwell indentation software, automatic measure to get data more easier and faster).

- Machine adopted high accuracy load cell and depth measuring system, ensure test result more accuracy.

- The machine adopts double handles plus magnetic switch, easy to operate, convenient to fix.

- With hardness conversion functions, freely convert to HV, HR, HBW, etc.

- Equipped with USB port, can save data to USB drive or through blue-tooth printer to print test data.

- The equipment adopts magnetic adsorption technology, combined with high-precision sensors and intelligent calibration system, to achieve fast, accurate and non-destructive hardness testing, especially suitable for on-site, on-line and complex working conditions hardness testing scenarios.

Specifications

| Model No. | BPR-150A-T |

| Version | Rockwell test with Benchtop base |

| Initial Test Force | 10kgf (98.07N) |

| Main Test Force | 60kgf(588.4N), 100kgf(980.7N), 150kgf (1471N) |

| Hardness Scale | HRA, HRB, HRC |

| Test Range | 20-95HRA, 10-100HRB, 20-70HRC |

| Indenter | 120? Rockwell diamond indenter, Ø1.5875mm Carbide Ball indenter |

| Force Control | Close loop load cell |

| Loading | Automatic loading - dwell - unloading test force |

| Data Transfer | Blue-tooth printer, USB port |

| Data Storage | 1000 pieces test data |

| Battery | Rechargeable lithium battery, Battery work continuous time 6 hours, Battery Charging Time 2 Hours |

| Machine Size /G.W | 208*115*267mm |

Accessories

- Machine Body: 1pc

- Diamond Indenter: 1pc

- 1.5875mm Carbide Ball Indenter: 1pc

- Hardness Block: 1pc

- Battery Charger: 1pc

Software Description

Download Cataloge

ENQUIRY

Automatic Portable Rockwell Hardness Tester