- Home

- Products

- Material Testing Machines

- Universal Testing Machine (UTM)

Description

BCF-UTM Series Universal Testing Machines supplied completed with UTM Software. It has a wide range of applications. A number of materials and metals in different forms and shapes can be tested for a variety of tests like tension, Compression, Transverse, Bend, Shear, Brinell Hardness, etc. Special attachments are also available for testing of flat belts, chain links, wire ropes etc.

Application

Universal Testing Machines have a wide range of applications and number of materials, metals in different form and shapes can be tested for variety of tests like Tension, Compression, Transverse, Bend, Shear, Brinell Hardness etc. Special attachments are also available for testing of Flat Belts, Chain Links, Wire

Features

Specifications

| Model No. | BCF-UTM-100 | BCF-UTM-200 | BCF-UTM-400 | BCF-UTM-600 | BCF-UTM-1000 | BCF-UTM-2000 |

| Measuring Cap. (kN) | 100 | 200 | 400 | 600 | 1000 | 2000 |

| Measuring Range. (kN) | 0 - 100 | 0 - 200 | 0 - 400 | 0 - 600 | 0 - 1000 | 0 - 2000 |

| Least Count (kN) | 0.005 | 0.01 | 0.016 | 0.024 | 0.04 | 0.08 |

| Load Range in kN with accuracy of Measurement ± 1% | 2 to 100 | 4 to 200 | 8 to 400 | 12 to 600 | 12 to 1000 | 40 to 2000 |

| Resolution of Piston movement (mm) | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Max. tensile clearance at fully descended piston position | 50 to 700 | 50 to 700 | 50 to 700 | 50 to 800 | 50 to 850 | 50 to 900 |

| Maximum clearance for Compression test (mm) | 0 - 700 | 0 - 700 | 0 - 700 | 0 - 800 | 0 - 850 | 0 - 900 |

| Distance between columns (mm) | 450 | 500 | 500 | 600 | 750 | 850 |

| Piston Stroke (mm) | 150 | 200 | 200 | 250 | 250 | 300 |

| Maximum straining speed at no load (mm/min) | 300 | 150 | 150 | 100 | 80 | 45 |

| Power Supply | 3 phase 415V 50 / 60 Hz A.c. | |||||

| H. P. (Total) | 1.5 | 1.5 | 2.5 | 2.5 | 4.0 | 6.5 |

| Overall dimensions (mm L x W x H) | 1950 x 800 x 1850 | 2000 x 800 x 1900 | 2100 x 800 x 2060 | 2200 x 800 x 2400 | 2350 x 800 x 2700 | 3000 x 800 x 3600 |

| Weight (Approx in kg) | 1300 | 1400 | 2000 | 3000 | 4200 | 10000 |

Accessories

| Model No. | BCF-UTM-100 | BCF-UTM-200 | BCF-UTM-400 | BCF-UTM-600 | BCF-UTM-1000 | BCF-UTM-2000 |

| Tension Test JAWS For : | ||||||

| Round specimen dia (mm) | 10 - 20 | 10 - 20 | 10 - 25 | 10 - 25 | 10 - 25 | 20 - 40 |

| Round specimen dia (mm) | 20 - 30 | 20 - 30 | 25 - 40 | 25 - 40 | 25 - 45 | 40 - 60 |

| Round specimen dia (mm) | - | - | - | 40 - 55 | 45 - 70 | 60 - 80 |

| Flat specimen Thickness (mm) | 0 - 10 | 0 - 10 | 0 - 15 | 0 - 15 | 0 - 22 | 0 - 22 |

| Flat specimen Thickness (mm) | 10 - 20 | 10 - 20 | 15 - 30 | 15 - 30 | 22 - 44 | 22 - 45 |

| Flat specimen Thickness (mm) | - | - | - | - | 44 - 65 | 45 - 70 |

| Max. width for Flat specimen (mm) | 50 | 50 | 65 | 70 | 70 | 90 |

| For Compression Test : | ||||||

| Pair of Compress Plates dia Ø(mm) | 120 | 120 | 120 | 120 | 160 | 220 |

| For Transverse Test : | ||||||

| Adjustment roller supports width (mm) | 150 | 150 | 150 | 160 | 160 | 200 |

| Diameter (mm) | 30 | 30 | 30 | 50 | 50 | 70 |

| With Max. adjustable clearance (mm) | 450 | 500 | 500 | 600 | 800 | 900 |

| Punch Taps of Radius (mm) | 6 | 6 | 6 | 16 | 16 | 30 |

| Radius (mm) | 12 | 12 | 12 | 22 | 22 | 40 |

Software Description

- Menu driven form system with color graphs to compare sample test results

- Test details and reports are stored in database

- User programmable master test templates

- User can select test from master test Templates and can start similar test

- Load and Elongation is continuously displayed on screen

- Overload protection for machine by electronic control

- Tare Load and Reset Elongation facility available

- User selectable sample break detect condition

- Load rate and strain rate are also displayed while testing

- Unlimited Load rate and strain rate control steps

- With Load rate controller, user can hold the load on specimen for unlimited time

- With Load rate control, user can specify positive or negative Rate of Loading

- User selectable units for load and displacement (kg, k N,N, I b f, mm, cm, inch etc.) Results and graphs are automatically displayed accordingly

- On line display of Load and Displacement (Stress, Extension, Strain) etc. while test is conducted

- Provision of auto zeroing of Elongation at preload set by user

- User Programmable Reports. User can select Header, Footer, Specimen information, Dimensions, Test information, Test results, Statically analysis as per his need

- Generated reports can be exported to PDF file and can be e-mailed

- If electronic extensometer is used then proof stress values from 0.1% to1%can be determined

- Software will give alert to user to remove extensometer when load crosses .2% of Gauge length selected then proof load value is calculated. (With extensometer)

- Separate graph of extensometer and encoder is displayed

- Provision of calculation of Load and Elongation at yield, Peak load and Load at break, Yield stress, Ultimate stress etc.

- Special software for tensile, compression, bend, TOR steel and other test software as per customer requirements

- Available with load rate / Strain Rate / Controller

Download Cataloge

ENQUIRY

Computerized Universal Testing Machine

Description

BCF-UTM- SERVO Series Universal Testing Machines supplied completed with UTM Software. It has a wide range of applications. A number of materials and metals in different forms and shapes can be tested for a variety of tests like tension, Compression, Transverse, Bend, Shear, Brinell Hardness, etc. Special attachments are also available for testing of flat belts, chain links, wire ropes etc.

Application

Universal Testing Machines have a wide range of applications and number of materials, metals in different form and shapes can be tested for variety of tests like Tension, Compression, Transverse, Bend, Shear, Brinell Hardness etc. Special attachments are also available for testing of Flat Belts, Chain Links, Wire Ropes etc.

Features

Specifications

| Model No. | BCF-UTM-100SERVO | BCF-UTM-200SERVO | BCF-UTM-400SERVO | BCF-UTM-600SERVO | BCF-UTM-1000SERVO | BCF-UTM-2000SERVO |

| Measuring Cap. (kN) | 100 | 200 | 400 | 600 | 1000 | 2000 |

| Measuring Range. (kN) | 0-100 | 0-200 | 0-400 | 0-600 | 0-1000 | 0-2000 |

| Least Count (kN) | 0.005 | 0.01 | 0.016 | 0.024 | 0.04 | 0.08 |

| Load Range in kN with accuracy of Measurement ± 1% | 2 to 100 | 4 to 200 | 8 to 400 | 12 to 600 | 20 to 1000 | 40 to 2000 |

| Resolution of Piston movement (mm) | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Max. tensile clearance at fully descended piston position | 50 to 700 | 50 to 700 | 50 to 700 | 50 to 800 | 50 to 850 | 50 to 900 |

| Maximum clearance for Compression test (mm) | 0 - 700 | 0-700 | 0-700 | 0-800 | 0-850 | 0-900 |

| Distance between columns (mm) | 450 | 500 | 500 | 600 | 750 | 850 |

| Piston Stroke (mm) | 150 | 200 | 200 | 250 | 250 | 300 |

| Maximum straining speed at no load (mm/min) | 300 | 150 | 150 | 100 | 80 | 45 |

| Power Supply | 3 phase 415V 50 / 60 Hz A.c. | |||||

| H. P. (Total) | 1.5 | 1.5 | 2.5 | 2.5 | 4.0 | 6.5 |

| Overall dimensions (Approx) (mm L x W x H) | 1950 * 800 * 1850 | 2000 * 800 * 1900 | 2100 * 800 * 2060 | 2200 * 800 * 2400 | 2350 * 800 * 2700 | 3000 * 800 * 3600 |

| Weight (Approx in kg) | 1300 | 1400 | 2000 | 3000 | 4200 | 10000 |

Accessories

| Model No. | BCF-UTM-100SERVO | BCF-UTM-200SERVO | BCF-UTM-400SERVO | BCF-UTM-600SERVO | BCF-UTM-1000SERVO | BCF-UTM-2000SERVO |

| Tension Test JAWS For : | ||||||

| Round specimen dia (mm) | 10 - 20 | 10-20 | 10-25 | 10-25 | 10-25 | 20-40 |

| Round specimen dia (mm) | 20-30 | 20-30 | 25-40 | 25-40 | 25-45 | 40-60 |

| Round specimen dia (mm) | - | - | - | 40-55 | 45-70 | 60-80 |

| Flat specimen Thickness (mm) | 0 - 10 | 0-10 | 0-15 | 0-15 | 0-22 | 0-22 |

| Flat specimen Thickness (mm) | 10 - 20 | 10-20 | 15-30 | 15-30 | 22-44 | 22-45 |

| Flat specimen Thickness (mm) | - | - | - | - | 44-65 | 45-70 |

| Max. width for Flat specimen (mm) | 50 | 50 | 65 | 70 | 70 | 90 |

| For Compression Test: | ||||||

| Pair of Compress Plates dia Ø(mm) | 120 | 120 | 120 | 120 | 160 | 220 |

| For Transverse Test: | ||||||

| Adjustment roller supports width (mm) | 150 | 150 | 150 | 160 | 160 | 160 |

| Diameter (mm) | 30 | 30 | 30 | 50 | 50 | 70 |

| With Max. adjustable clearance (mm) | 450 | 500 | 500 | 600 | 800 | 900 |

| Punch Taps of Radius (mm) | 6 | 6 | 6 | 16 | 16 | 30 |

| Radius (mm) | 12 | 12 | 12 | 22 | 22 | 40 |

Software Description

- Menu driven form system with colour graphs to compare sample test results

- Test details and reports are stored in database

- User programmable master test templates

- User can select test from master test Templates and can start similar test

- Load and Elongation is continuously displayed on screen

- Overload protection for machine by electronic control

- Tare Load and Reset Elongation facility available

- User selectable sample break detect condition

- Load rate and strain rate are also displayed while testing

- Unlimited Load rate and strain rate control steps

- With Load rate controller, user can hold the load on specimen for unlimited time

- With Load rate control, user can specify positive or negative Rate of Loading

- User selectable units for load and displacement (kg, k N, N, I b f, mm, cm, inch etc.) Results and graphs are automatically displayed accordingly

- On line display of Load and Displacement (Stress, Extension, Strain) etc. while test is conducted

- Provision of auto zeroing of Elongation at preload set by user

- User Programmable Reports. User can select Header, Footer, Specimen information, Dimensions, Test information, Test results, Statically analysis as per his need

- Generated reports can be exported to PDF file and can be e-mailed

- If electronic extensometer is used then proof stress values from 0.1% to1%can be determined

- Software will give alert to user to remove extensometer when load crosses .2% of Gauge length selected then proof load value is calculated. (With extensometer)

- Separate graph of extensometer and encoder is displayed

- Provision of calculation of Load and Elongation at yield, Peak load and Load at break, Yield stress, Ultimate stress etc.

- Special software for tensile, compression, bend, TOR steel and other test software as per customer requirements

- Available with load rate / Strain Rate / Controller.

Download Cataloge

ENQUIRY

Computerized Universal Testing Machine With Servo System

Description

BCF-UTM- HG Series Universal Testing Machines supplied completed with UTM Software. It has a wide range of applications. A number of materials and metals in different forms and shapes can be tested for a variety of tests like tension, Compression, Transverse, Bend, Shear, Brinell Hardness, etc. Special attachments are also available for testing of flat belts, chain links, wire ropes etc.

Application

Universal Testing Machines have a wide range of applications and number of materials, metals in different form and shapes can be tested for variety of tests like Tension, Compression, Transverse, Bend, Shear, Brinell Hardness etc. Special attachments are also available for testing of Flat Belts, Chain Links, Wire Ropes etc.

Features

Specifications

| Model No. | BCF-UTM- 100 HG | BCF-UTM-200 HG | BCF-UTM-400 HG | BCF-UTM-600 HG | BCF-UTM-1000 HG | BCF-UTM-2000 HG |

| Measuring Cap. (kN) | 100 | 200 | 400 | 600 | 1000 | 2000 |

| Measuring Range. (kN) | 0 - 100 | 0 - 200 | 0 - 400 | 0 - 600 | 0 - 1000 | 0 - 2000 |

| Least Count (kN) | 0.005 | 0.01 | 0.016 | 0.024 | 0.04 | 0.08 |

| Load Range in kN with accuracy of Measurement ± 1% | 2 to 100 | 4 to 200 | 8 to 400 | 12 to 600 | 12 to 1000 | 40 to 2000 |

| Resolution of Piston movement (mm) | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Max. tensile clearance at fully descended piston position | 50 to 700 | 50 to 700 | 50 to 700 | 50 to 800 | 50 to 850 | 50 to 900 |

| Maximum clearance for Compression test (mm) | 0 - 700 | 0 - 700 | 0 - 700 | 0 - 800 | 0 - 850 | 0 - 900 |

| Distance between columns (mm) | 450 | 500 | 500 | 600 | 750 | 850 |

| Piston Stroke (mm) | 150 | 200 | 200 | 250 | 250 | 300 |

| Maximum straining speed at no load (mm/min) | 300 | 150 | 150 | 100 | 80 | 45 |

| Power Supply | 3 phase 415V 50 / 60 Hz A.c. | |||||

| H. P. (Total) | 1.5 | 1.5 | 2.5 | 2.5 | 4.0 | 6.5 |

| Overall dimensions (mm L x W x H) | 1950 x 800 x 1850 | 2000 x 800 x 1900 | 2100 x 800 x 2060 | 2200 x 800 x 2400 | 2350 x 800 x 2700 | 3000 x 800 x 3600 |

| Weight (Approx in kg) | 1300 | 1400 | 2000 | 3000 | 4200 | 10000 |

Accessories

| Model No. | BCF-UTM-100 HG | BCF-UTM- 200 HG | BCF-UTM- 400 HG | BCF-UTM- 600 HG | BCF-UTM- 1000 HG | BCF-UTM- 2000 HG |

| Tension Test JAWS For : | ||||||

| Round specimen dia (mm) | 10 - 20 | 10 - 20 | 10 - 25 | 10 - 25 | 10 - 25 | 20 - 40 |

| Round specimen dia (mm) | 20 - 30 | 20 - 30 | 25 - 40 | 25 - 40 | 25 - 45 | 40 - 60 |

| Round specimen dia (mm) | - | - | - | 40 - 55 | 45 - 70 | 60 - 80 |

| Flat specimen Thickness (mm) | 0 - 10 | 0 - 10 | 0 - 15 | 0 - 15 | 0 - 22 | 0 - 22 |

| Flat specimen Thickness (mm) | 10 - 20 | 10 - 20 | 15 - 30 | 15 - 30 | 22 - 44 | 22 - 45 |

| Flat specimen Thickness (mm) | - | - | - | - | 44 - 65 | 45 - 70 |

| Max. width for Flat specimen (mm) | 50 | 50 | 65 | 70 | 70 | 90 |

| For Compression Test : | ||||||

| Pair of Compress Plates dia Ø(mm) | 120 | 120 | 120 | 120 | 160 | 220 |

| For Transverse Test : | ||||||

| Adjustment roller supports width (mm) | 150 | 150 | 150 | 160 | 160 | 200 |

| Diameter (mm) | 30 | 30 | 30 | 50 | 50 | 70 |

| With Max. adjustable clearance (mm) | 450 | 500 | 500 | 600 | 800 | 900 |

| Punch Taps of Radius (mm) | 6 | 6 | 6 | 16 | 16 | 30 |

| Radius (mm) | 12 | 12 | 12 | 22 | 22 | 40 |

Software Description

- Menu driven form system with color graphs to compare sample test results

- Test details and reports are stored in database

- User programmable master test templates

- User can select test from master test Templates and can start similar test

- Load and Elongation is continuously displayed on screen

- Overload protection for machine by electronic control

- Tare Load and Reset Elongation facility available

- User selectable sample break detect condition

- Load rate and strain rate are also displayed while testing

- Unlimited Load rate and strain rate control steps

- With Load rate controller, user can hold the load on specimen for unlimited time

- With Load rate control, user can specify positive or negative Rate of Loading

- User selectable units for load and displacement (kg, k N,N, I b f, mm, cm, inch etc.) Results and graphs are automatically displayed accordingly

- On line display of Load and Displacement (Stress, Extension, Strain) etc. while test is conducted

- Provision of auto zeroing of Elongation at preload set by user

- User Programmable Reports. User can select Header, Footer, Specimen information, Dimensions, Test information, Test results, Statically analysis as per his need

- Generated reports can be exported to PDF file and can be e-mailed

- If electronic extensometer is used then proof stress values from 0.1% to1%can be determined

- Software will give alert to user to remove extensometer when load crosses .2% of Gauge length selected then proof load value is calculated. (With extensometer)

- Separate graph of extensometer and encoder is displayed

- Provision of calculation of Load and Elongation at yield, Peak load and Load at break, Yield stress, Ultimate stress etc.

- Special software for tensile, compression, bend, TOR steel and other test software as per customer requirements

- Available with load rate / Strain Rate / Controller

Download Cataloge

ENQUIRY

Computerized Universal Testing Machine Front Open with Hydraulic Grip

Description

Our BCF-UTM -HG-SERVO Series Model is hydraulically controlled servo Universal Testing Machine. The main advantage of this servo system is a test can be conducted by giving a specific load rate or elongation rate. The oil flow is controlled by the close loop feedback from the load elongation system. Test with specific load steps can also be conducted.

Application

Universal Testing Machines have a wide range of applications and number of materials, metals in different form and shapes can be tested for variety of tests like Tension, Compression, Transverse, Bend, Shear, Brinell Hardness etc. Special attachments are also available for testing of Flat Belts, Chain Links, Wire Ropes etc.

Features

Specifications

| Model No. | BCF-UTM-100 HG SERVO | BCF-UTM-200 HG SERVO | BCF-UTM-400 HG SERVO | BCF-UTM-600 HG SERVO | BCF-UTM-1000 HG SERVO | BCF-UTM-2000 HG SERVO |

| Measuring Cap. (kN) | 100 | 200 | 400 | 600 | 1000 | 2000 |

| Measuring Range. (kN) | 0-100 | 0-200 | 0-400 | 0-600 | 0-1000 | 0-2000 |

| Least Count (kN) | 0.005 | 0.01 | 0.016 | 0.024 | 0.04 | 0.08 |

| Load Range in kN with accuracy of Measurement ± 1% | 2 to 100 | 4 to 200 | 8 to 400 | 12 to 600 | 12 to 600 | 40 to 2000 |

| Resolution of Piston movement (mm) | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Max. tensile clearance at fully descended piston position | 50 to 700 | 50 to 700 | 50 to 700 | 50 to 800 | 50 to 850 | 50 to 900 |

| Maximum clearance for Compression test (mm) | 0 - 700 | 0 - 700 | 0 - 700 | 0-800 | 0-850 | 0-900 |

| Distance between columns (mm) | 450 | 500 | 500 | 600 | 750 | 850 |

| Piston Stroke (mm) | 150 | 200 | 200 | 250 | 250 | 300 |

| Maximum straining speed at no load (mm/min) | 300 | 150 | 150 | 100 | 80 | 45 |

| Power Supply | 3 phase 415V 50 / 60 Hz A.c. | |||||

| H. P. (Total) | 1.5 | 1.5 | 2.5 | 2.5 | 4.0 | 6.5 |

| Overall dimensions (mm L x W x H) | 1950 * 800 * 1850 | 2000 * 800 * 1900 | 2100 * 800 * 2060 | 2200 * 800 * 2400 | 2350 * 800 * 2700 | 3000 * 800 * 3600 |

| Weight (Approx in kg) | 1300 | 1400 | 2000 | 3000 | 4200 | 10000 |

Accessories

| Model No. | BCF-UTM-100 HG SERVO | BCF-UTM-200 HG SERVO | BCF-UTM-400 HG SERVO | BCF-UTM-600 HG SERVO | BCF-UTM-1000 HG SERVO | BCF-UTM-2000 HG SERVO |

| Tension Test JAWS For : | ||||||

| Round specimen dia (mm) | 10 - 20 | 10-20 | 10-25 | 10-25 | 10-25 | 20-40 |

| Round specimen dia (mm) | 20-30 | 20-30 | 25-40 | 25-40 | 25-45 | 40-60 |

| Round specimen dia (mm) | - | - | - | 40-55 | 45-70 | 60-80 |

| Flat specimen Thickness (mm) | 0 - 10 | 0 - 10 | 0-15 | 0-15 | 0-22 | 0-22 |

| Flat specimen Thickness (mm) | 10 - 20 | 10 - 20 | 15-30 | 15-30 | 22-44 | 22-45 |

| Flat specimen Thickness (mm) | - | - | - | - | 44-65 | 45-70 |

| Max. width for Flat specimen (mm) | 50 | 50 | 65 | 70 | 70 | 90 |

| For Compression Test: | ||||||

| Pair of Compress Plates dia Ø(mm) | 120 | 120 | 120 | 120 | 160 | 220 |

| For Transverse Test: | ||||||

| Adjustment roller supports width (mm) | 150 | 150 | 150 | 160 | 160 | 200 |

| Diameter (mm) | 30 | 30 | 30 | 50 | 50 | 70 |

| With Max. adjustable clearance (mm) | 450 | 500 | 500 | 600 | 800 | 900 |

| Punch Taps of Radius (mm) | 6 | 6 | 6 | 16 | 16 | 30 |

| Radius (mm) | 12 | 12 | 12 | 22 | 22 | 40 |

Software Description

- Menu driven form system with colour graphs to compare sample test results

- Test details and reports are stored in database

- User programmable master test templates

- User can select test from master test Templates and can start similar test

- Load and Elongation is continuously displayed on screen

- Overload protection for machine by electronic control

- Tare Load and Reset Elongation facility available

- User selectable sample break detect condition

- Load rate and strain rate are also displayed while testing

- Unlimited Load rate and strain rate control steps

- With Load rate controller, user can hold the load on specimen for unlimited time

- With Load rate control, user can specify positive or negative Rate of Loading

- User selectable units for load and displacement (kg, k N, N, I b f, mm, cm, inch etc.) Results and graphs are automatically displayed accordingly

- On line display of Load and Displacement (Stress, Extension, Strain) etc. while test is conducted

- Provision of auto zeroing of Elongation at preload set by user

- User Programmable Reports. User can select Header, Footer, Specimen information, Dimensions, Test information, Test results, Statically analysis as per his need

- Generated reports can be exported to PDF file and can be e-mailed

- If electronic extensometer is used then proof stress values from 0.1% to1%can be determined

- Software will give alert to user to remove extensometer when load crosses .2% of Gauge length selected then proof load value is calculated. (With extensometer)

- Separate graph of extensometer and encoder is displayed

- Provision of calculation of Load and Elongation at yield, Peak load and Load at break, Yield stress, Ultimate stress etc.

- Special software for tensile, compression, bend, TOR steel and other test software as per customer requirements

- Available with load rate / Strain Rate / Controller.

Download Cataloge

ENQUIRY

Computerized Universal Testing Machine Front Open with Hydraulic Grip & Servo System

Description

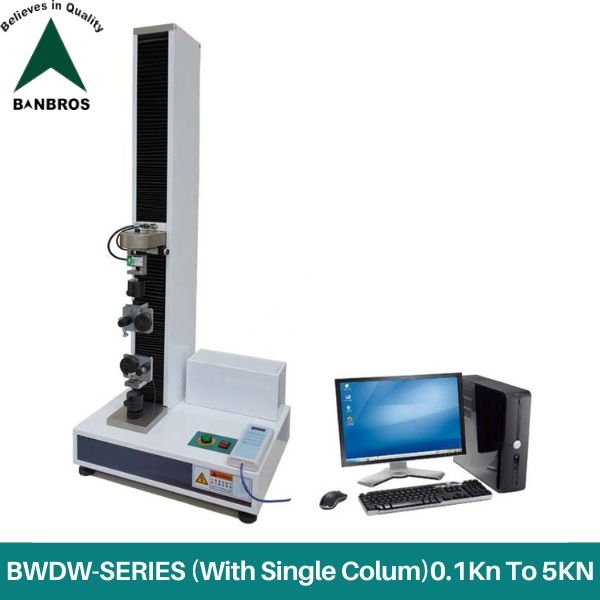

BWDW Series Computer Control Electronic Universal Testing Machine made by BANBROS with various models like single columns, double columns, floor model, table top, door frame type etc., is used to perform tension, compression, flexure/bending, shearing, peeling, tear, cyclic etc., test for metal and non-metal specimens.

This Series Floor Model & Dual Column testing systems provide simplicity, performance and affordability for quality control (QC) labs and production testing.

These models are robust, heavy-duty frames commonly used for testing high-strength metals and alloys, advanced composites, aerospace and automotive structures, bolts, fasteners, and plate steels. Frames are available in load capacities of 10Kn to 300Kn; and several variations are available to accommodate requirements for both extended travel and extra wide test space.

Load weighing system meets or exceeds the requirements of the following standards: ASTM E4, EN10002-2, BS 1610, DIN 51221, and ISO 7500-1.

Application

These Machines are suitable to use in Medical devices Industries, Biomaterials, textiles, elastomers, food, small components, wire, paper, plastic, film, fibre and threads, adhesives and many more.

Widely used for industrial application, factory quality control, science and research institute, QC &QA college student training, education institute, testing and inspection center, laboratories, construction company, aerospace, mechanical production, electric appliance fields.

Comply with different standards such as ASTM D638, ASTM D695, ASTM D790, ASTM D412, 624, ASTM D882, ISO 527, ISO 37, ISO 604, ISO 178 and other equivalent BS, ASTM, JIS standard.

Features

1) LOAD FRAME AND DRIVEN TYPE

- Frame are proof loaded to 300% of capacity, with concentric arrangement of the drive lead screw and crosshead guide which assure high accuracy and strong reliability.

- Top and middle crosshead processed through shot blasting & baking paint technology, appearance, no corrosion and no need lubrication oil maintenance.

- Adopt Japan Panasonic/FUJI AC servo motor and driving system, ensure transmission and moment of force stable.

- Adopt Circular Arc Profile Synchronous Belt Transmission, eliminate dual direction clearance, prolongs the life of synchronous belt.

- Multiple load cell in one machine available.

- Advanced USA Vishay celtron load cell ensure the force measuring accuracy and repeatability, Overload capacity 150%.

- Compatibility concept for continuous component expansion.

2) GRIP AND TEST FIXTURE

- Manual, hydraulic, pneumatic tensile test fixture available.

- Removable grip-jaws can be changed rapidly to meet variable wider applications in tension test.

- Versatile test fixture like peeling, shear, bending, flexure, tear, burst, puncture, compression test for kinds of material.

3) SECURITY FUNCTION

- Sensor of position limitation switch.

- Emergency stop switch.

- Hardware driving system overload protection, over voltage, current protection.

- Software over load protection.

4) CONTROL SYSTEM, SOFTWARE

- Based on full digital STC8800 measuring and control card; Data collection system use 4 channels of high accuracy 24-digit A/D converter.

- Real time load, deformation, crosshead displacement, test process four kind close loop control.

- Resolution can upto 1/500000, full range without step.

- Level authorization management function: to improve software and data security, can set different password to realize several class authorization management. Different user with different right to operate the machine, avoiding unexpected mistake because human error.

- PC control system, with advantage of high integration, reliable performance, easy adjustment etc. can real time collect test data, on-time display test curve, test data file can be saved as ACCESS and SQL server, convenient for customer's data resource storage.

- Automatically generate the testing report; the testing report can be displayed and printed, also it can be export in Excel/Access Format. Also, the user can edit the report format as requirement in report template.

- Result recall function: after the test and saved, customer can open the test data and re-analysis at any time.

- Results compare: observe several curves at same time, can fold curve or portion enlarge to analyse and compare sample characters.

- Lead-times, Load displacement, Displacement time etc. curve smoothly switch, display test data, save, analysis and print.

5) POWERFUL FUNCTION SOFTWARE

Specifications

| Model No. | BWDW-10KN | BWDW-20KN | BWDW-30KN | BWDW-50KN | BWDW-100KN | BWDW-200KN | BWDW-300KN |

| Load capacity | 10KN | 20KN | 30KN | 50KN | 100KN | 200KN | 300KN |

| Multiple load cell in one machine function | YES | ||||||

| Load Accuracy | Class 1/0.5 according ISO7500-1 | ||||||

| Load cell overload capacity | 150% of rate capacity | ||||||

| Load measuring resolution | 1/500000 FS, stepless | ||||||

| Position / displacement resolution | 0.001mm | ||||||

| Crosshead travel | 1200mm | 1250mm | |||||

| Tensile test space | 700mm | 750mm | |||||

| Compression test space | 800mm | 850mm | |||||

| Effective test width(Clearance b/w columns) | 500mm | 600mm | |||||

| Standard tensile test fixture | Manual wedge type | Manual wedge type (Optional: Hydraulic automatic wedge grip) | |||||

| Wedge tensile fixture flat specimen range | 0-20mm | 0-20mm | 0-26mm | ||||

| Wedge tensile fixture round specimen range | Φ4- Φ20mm | Φ4-Φ26mm | Φ4- Φ32mm | ||||

| Compression platen diameter | Φ100mm | Φ120mm | |||||

| Testing speed range | 0.001mm/min ~ 500mm/min, stepless, adjustable arbitrarily (Optional max. 1000mm/min) | ||||||

| Weight | 450Kg ~650Kg | 1200Kg | 1300Kg | ||||

| Standard Power | 220/110V, 50/60HZ, 1 phase | 220V, 50, 1 phase | |||||

| Analysis software | Smart Test English version | ||||||

| Frame structure | Standard: Dual test space, Optional: Single test space | ||||||

Accessories

- High stiffness frame : 1 set

- Servo driving system & Servo motor : 1 set

- Loadcell : 1 set

- Decelerator and deceleration system : 1 set

- Leading screw : 1 set

- Wedge tensile test fixture : 1 set

- Compression test fixture(Φ100mm) : 1 set

- Bending test fixture : 1 set

- USB Hand remote controller : 1 set

- Tool kit (screwdriver, spanner etc.) : 1 set

- STC8800 control card : 1 set

- Professional testing software(Smart Test, English version) : 1 set

- Documents (Manual, Test certificate) : 1 set

Software Description

- Based on full digital STC8800 measuring and control card; Data collection system use 4 channels of high accuracy 24-digit A/D converter.

- Real time load, deformation, crosshead displacement, test process four kind close loop control.

- Resolution can upto 1/500000, full range without step.

- Level authorization management function: to improve software and data security, can set different password to realize several class authorization management. Different user with different right to operate the machine, avoiding unexpected mistake because human error.

- PC control system, with advantage of high integration, reliable performance, easy adjustment etc. can real time collect test data, on-time display test curve, test data file can be saved as ACCESS and SQL server, convenient for customer's data resource storage.

- Automatically generate the testing report; the testing report can be displayed and printed, also it can be export in Excel/Access Format. Also, the user can edit the report format as requirement in report template.

- Result recall function: after the test and saved, customer can open the test data and re-analysis at any time.

- Results compare: observe several curves at same time, can fold curve or portion enlarge to analyse and compare sample characters.

- Lead-times, Load displacement, Displacement time etc. curve smoothly switch, display test data, save, analysis and print.

Download Cataloge

ENQUIRY

Computerized Universal Testing Machine With Servo System

Description

BWDW- HS Series Computer Control Electronic Universal Testing Machine made by BANBROS with various models like single columns, double columns, floor structure, table top, door frame type etc., is used to perform tension, compression, flexure/bending, shearing, peeling, tear, cyclic etc., test for metal and nonmetal specimens.

This Series Floor Model & Dual Column testing systems provide simplicity, performance and affordability for quality control (QC) labs and production testing.

These models are robust, heavy-duty frames commonly used for testing high-strength metals and alloys, advanced composites, aerospace and automotive structures, bolts, fasteners, and plate steels. Frames are available in load capacities of 400Kn, 500Kn, 600Kn, 1000Kn; and several variations are available to accommodate requirements for both extended travel and extra wide test space.

Load weighing system meets or exceeds the requirements of the following standards: ASTM E4, EN10002-2, BS 1610, DIN 51221, and ISO 7500-1.

Application

These Machines are suitable to use in medical devices, biomaterials, textiles, elastomers, food, small components, wire, paper, plastic, film, fibers and threads, adhesives and many more.

Widely used for industrial application, factory quality control, science and research institute, QC & QA college student training, education institute, testing and inspection center, laboratories, construction company, aerospace, mechanical production, electric appliance fields.

Comply with different standards such as ASTM D638, ASTM D695, ASTM D790, ASTM D412, 624, ASTM D882, ISO 527, ISO 37, ISO 604, ISO 178 and other equivalent BS, ASTM, JIS standard.

Features

1) LOAD FRAME AND DRIVEN TYPE

- Frame are proof loaded to 300% of capacity, with concentric arrangement of the drive lead screw and crosshead guide which assure high accuracy and strong reliability.

- Top and middle crosshead processed through shot blasting & baking paint technology, appearance, no corrosion and no need lubrication oil maintenance.

- Adopt Japan Panasonic/FUJI AC servo motor and driving system, ensure transmission and moment of force stable.

- Adopt Circular Arc Profile Synchronous Belt Transmission, eliminate dual direction clearance, prolongs the life of synchronous belt.

- Multiple load cell in one machine available.

- Advanced USA Vishay celtron load cell ensure the force measuring accuracy and repeatability, Overload capacity 150%.

- Compatibility concept for continuous component expansion.

2) GRIP AND TEST FIXTURE

- Manual, hydraulic, pneumatic tensile test fixture available.

- Removable grip-jaws can be changed rapidly to meet variable wider applications in tension test.

- Versatile test fixture like peeling, shear, bending, flexure, tear, burst, puncture, compression test for kinds of material.

3) SECURITY FUNCTION

- Sensor of position limitation switch.

- Emergency stop switch.

- Hardware driving system overload protection, over voltage, current protection.

- Software over load protection.

4) CONTROL SYSTEM, SOFTWARE

- Based on full digital STC8800 measuring and control card; Data collection system use 4 channels of high accuracy 24-digit A/D converter.

- Real time load, deformation, crosshead displacement, test process four kind close loop control.

- Resolution can upto 1/500000, full range without step.

- Level authorization management function: to improve software and data security, can set different password to realize several class authorization management. Different user with different right to operate the machine, avoiding unexpected mistake because human error.

- PC control system, with advantage of high integration, reliable performance, easy adjustment etc. can real time collect test data, on-time display test curve, test data file can be saved as ACCESS and SQL server, convenient for customer's data resource storage.

- Automatically generate the testing report; the testing report can be displayed and printed, also it can be export in Excel/Access Format. Also, the user can edit the report format as requirement in report template.

- Result recall function: after the test and saved, customer can open the test data and re-analysis at any time.

- Results compare: observe several curves at same time, can fold curve or portion enlarge to analyse and compare sample characters.

- Lead-times, Load displacement, Displacement time etc. curve smoothly switch, display test data, save, analysis and print.

5) POWERFUL FUNCTION SOFTWARE

Specifications

| Model No. | BWDW-500KN-HS | BWDW-600KN-HS | ||||||

| Load capacity | 500KN | 600KN | ||||||

| Multiple load cell in one machine function | YES | |||||||

| Load Accuracy | Class 1/0.5 according ISO7500-1 | |||||||

| Load cell overload capacity | 150% of rate capacity | |||||||

| Load measuring resolution | 1/500000 FS, stepless | |||||||

| Position / displacement resolution | 0.001mm | |||||||

| Crosshead travel | 1100mm | |||||||

| Tensile test space | 600mm | |||||||

| Compression test space | 700mm | |||||||

| Effective test width(Clearance b/w columns) | 600mm | |||||||

| Standard tensile test fixture | Automatic hydraulic type translational moving grip | |||||||

| Wedge tensile fixture flat specimen range | 0-40mm | |||||||

| Wedge tensile fixture round specimen range | Φ20- Φ50mm | |||||||

| Compression platen diameter | Φ150mm | |||||||

| Testing speed range | 0.05mm/min ~ 300mm/min, stepless, adjustable arbitrarily | |||||||

| Weight | 1300Kg | |||||||

| Dimensions | 1200x1050x2550mm | |||||||

| Standard Power | 380/220V, 50/60HZ, 3 phase, 4Kw | |||||||

| Analysis software | Smart Test English version | |||||||

| Frame structure | Single test space | |||||||

Accessories

- High stiffness frame : 1 set

- Servo driving system & Servo motor : 1 set

- Loadcell : 1 set

- Decelerator and deceleration system : 1 set

- Leading screw : 1 set

- Wedge tensile test fixture : 1 set

- Compression test fixture(Φ100mm) : 1 set

- Bending test fixture : 1 set

- USB Hand remote controller : 1 set

- Tool kit (screwdriver, spanner etc.) : 1 set

- STC8800 control card : 1 set

- Professional testing software(Smart Test, English version) : 1 set

- Documents (Manual, Test certificate) : 1 set

Software Description

- Based on full digital STC8800 measuring and control card; Data collection system use 4 channels of high accuracy 24-digit A/D converter.

- Real time load, deformation, crosshead displacement, test process four kind close loop control.

- Resolution can upto 1/500000, full range without step.

- Level authorization management function: to improve software and data security, can set different password to realize several class authorization management. Different user with different right to operate the machine, avoiding unexpected mistake because human error.

- PC control system, with advantage of high integration, reliable performance, easy adjustment etc. can real time collect test data, on-time display test curve, test data file can be saved as ACCESS and SQL server, convenient for customer's data resource storage.

- Automatically generate the testing report; the testing report can be displayed and printed, also it can be export in Excel/Access Format. Also, the user can edit the report format as requirement in report template.

- Result recall function: after the test and saved, customer can open the test data and re-analysis at any time.

- Results compare: observe several curves at same time, can fold curve or portion enlarge to analyse and compare sample characters.

- Lead-times, Load displacement, Displacement time etc. curve smoothly switch, display test data, save, analysis and print.

Download Cataloge

ENQUIRY

Computerized Universal Testing Machine With Hydraulic Servo System

Description

Single Column Tabletop universal testing systems can be used over a range of force applications up to 5 kN (500 kg). A variety of load cells are available to provide accurate measurements for applications ranging from micron-size fibers to those utilizing the full capacity of the load frame. Additionally, a full range of grips, fixtures, and strain measurement devices are also available.

Load weighing system meets or exceeds the requirements of the following standards: ASTM E4, EN10002-2, BS 1610, DIN 51221, ISO 7500-1.

Application

Widely used for industrial application, factory quality control, science and research institute, QC &QA college student training, education institute, testing and inspection center, laboratories, construction company, aerospace, mechanical production, electric appliance fields.

Comply with different standards such as ASTM D638, ASTM D695, ASTM D790, ASTM D412, 624, ASTM D882, ISO 527, ISO 37, ISO 604, ISO 178 and other equivalent BS, ASTM, JIS standard.

Features

- Compact construction, beautiful appearance load frame

- Frame are proof loaded to 200% of capacity, with concentric arrangement of the drive lead screw and crosshead guide which assure high accuracy and strong reliability.

- Top and middle crosshead processed through shot blasting & nickel coating technology, good looking, no corrosion and no need lubrication oil maintenance.

- Adopt Japan Panasonic/FUJI AC servo motor and driving system, ensure transmission and moment of force stable.

- Adopt Circular Arc Profile Synchronous Belt Transmission, eliminate dual direction clearance, prolongs the life of synchronous belt.

- Multiple load cell in one machine available.

- Advanced USA Vishay celtron load cell ensure the force measuring accuracy and repeatability, Overload capacity 150%.

- Advanced USA Vishay celtron load cell ensure the force measuring accuracy and repeatability, Overload capacity 150%.

- Compatibility concept for continuous component expansion

Specifications

| Model No. | BWDW-0.1KN | BWDW-0.2KN | BWDW-0.5KN | BWDW-1KN | BWDW-2KN | BWDW-5KN |

| Load Range | 100N | 200N | 500N | 1KN | 2KN | 5KN |

| Frame proof load capacity | 150% of rate capacity | |||||

| Multiple load cell in one machine function | YES | |||||

| Load Accuracy | Class 1/0.5 according ISO7500-1 | |||||

| Load cell overload capacity | 150% of rate capacity | |||||

| Load measuring resolution | 1/500000 FS, stepless | |||||

| Position / displacement resolution | 0.001mm | |||||

| Crosshead travel | 1150mm | |||||

| Tensile test space | 800mm | |||||

| Compression test space | 900mm | |||||

| Standard tensile test fixture | Corrugated Opposite clamping | |||||

| Compression platen diameter | Φ100mm | |||||

| Testing speed range | 0.001 mm/min?500 mm/min, stepless, adjustable arbitrarily | |||||

| Weight | 110kg | |||||

| Standard Power | 220/110V, 50/60HZ, 1 phase | |||||

| Dimensions | 520×410×1500mm | |||||

| Analysis software | Smart Test | |||||

| Working system | MS Win7 / Win10 | |||||

| Load measurement accuracy |

+/- 0.5% of applied load from 2% to 100% capacity; extended rangedown to 1%capacity with accuracy of 1% of applied load |

|||||

| Position measurement accuracy | +/- 0.01% of reading or 0.001 mm, whichever is greater | |||||

|

Deformation measuring accuracy and measuring range |

2%?100%FS, ≤±0.5% | |||||

| Strain measurement accuracy | +/- 0.5% of indicated load from 0.2% to 100% capacity FS | |||||

| Speed accuracy | ±1%(0.001~10mm/min), ±0.5%(10~500mm/min) | |||||

| Operating temperature range | 0 to 38 degrees C (32 to 100 degrees F) | |||||

| Storage temperature range | -10 to 45 degrees C (14 to 115 degrees F) | |||||

| Humidity range | 10% to 90% non-condensing, wet bulb method | |||||

| Power | standard optional voltages110/220VAC, 50-60 Hz; power must be free of spikes and surges exceeding 10% of the nominal voltage. | |||||

Accessories

Software Description

Download Cataloge

ENQUIRY

Computerized Universal Testing Machine with Single Column Servo

Description

BWDW Series Computer Control Electronic Universal Testing Machine made by Banbros range from 100N to 600KN load capacity with various models like single columns, table type, door frame type etc., is used to perform tension, compression, flexure/bending, shearing, peeling etc., test for metal and nonmetal specimens.

Matched with Banbros design and produced various test fixture, like peel, flexure, puncture, tear, pneumatic grip, belt tension etc., this UTM can be used to almost all materials include but not limited to steel rod, rubber, steel wire, plastic, seat belt, textile, wood, panel etc., mechanical performance inspection

Application

Widely used for industrial application, factory quality control, science and research institute, QC &QA college student training, education institute, testing and inspection center, laboratories, construction company, aerospace, mechanical production, electric appliance fields.

Features

- Robust frame with high stiffness; concentric arrangement of the drive lead screw and crosshead guide which assure high accuracy and strong reliability;

- Top and middle crosshead processed through shot blasting & baking paint technology, appearance, no corrosion and no need lubrication oil maintenance.

- Adopt Japan Panasonic/FUJI AC servo motor and driving system, ensure transmission and moment of force stable; 4), Adopt Circular Arc Profile Synchronous Belt Transmission, eliminate dual direction clearance, prolongs the life of synchronous belt;

- Multiple load cell in one machine available.

- Advanced USA Vishay celtron load cell ensure the force measuring accuracy and repeatability, Overload capacity 150%.

- Compatibility concept for continuous component expansion;

Specifications

| Load capacity | 400KN (0.4%--100%) |

| Multiple load cell in one machine function | YES |

| Load Accuracy | Class 1/0.5 according ISO7500-1 |

| Load cell overload capacity | 150% of rate capacity |

| Load measuring resolution | 1/500000 FS, stepless |

| Position / displacement resolution | 0.001mm |

| Crosshead travel | 1100mm |

| Tensile test space | 700mm |

| Compression test space | 750mm |

| Effective test width(Clearance b/w columns) | 600mm |

| Standard tensile test fixture | Hydraulic automatic grip |

| Wedge tensile fixture flat specimen range | 10-40mm |

| Wedge tensile fixture round specimen range | Φ10-Φ40mm |

| Compression platen diameter | Φ120mm |

| Testing speed range |

0.001 mm/min ~ 300 mm/min, stepless, adjustable arbitrarily |

| Weight | 3500kg |

| Standard Power | 380/220V, 50/60HZ, 3 phase |

| Analysis software | 1200×900×2400mm |

| Working system | MS Win7 / Win10 |

| Frame structure | Single test space |

Accessories

Software Description

Download Cataloge

ENQUIRY

Computer Controlled Electronic Universal Testing Machine

Description

WDW Series Computer Control Electronic Universal Testing Machine made by BANBROS range from 100N to 600KN load capacity with various models like single columns, table type, door frame type etc., is used to perform tension, compression, flexure/bending, shearing, peeling etc., test for metal and nonmetal specimens.

Matched with BANBROS design and produced various test fixture, like peel, flexure, puncture, tear, pneumatic grip, belt tension etc., this UTM can be used to almost all materials include but not limited to steel rod, rubber, steel wire, plastic, seat belt, textile, wood, panel etc., mechanical performance inspection.

Load weighing system meets or exceeds the requirements of the following standards: ASTM E4, EN10002-2, BS 1610, DIN 51221, ISO 7500-1.

Application

Widely used for industrial application, factory quality control, science and research institute, QC &QA college student training, education institute, testing and inspection center, laboratories, construction company, aerospace, mechanical production, electric appliance fields.

Comply with different standards such as ASTM D638, ASTM D695, ASTM D790, ASTM D412, 624, ASTM D882, ISO 527, ISO 37, ISO 604, ISO 178 and other equivalent BS, ASTM, JIS standard.

Features

- Compact construction, beautiful appearance load frame

- Frame are proof loaded to 200% of capacity, with concentric arrangement of the drive lead screw and crosshead guide which assure high accuracy and strong reliability.

- Top and middle crosshead processed through shot blasting & nickel coating technology, good looking, no corrosion and no need lubrication oil maintenance.

- Adopt Japan Panasonic/FUJI AC servo motor and driving system, ensure transmission and moment of force stable.

- Adopt Circular Arc Profile Synchronous Belt Transmission, eliminate dual direction clearance, prolongs the life of synchronous belt.

- Multiple load cell in one machine available.

- Advanced USA Vishay celtron load cell ensure the force measuring accuracy and repeatability, Overload capacity 150%.

- Advanced USA Vishay celtron load cell ensure the force measuring accuracy and repeatability, Overload capacity 150%.

- Compatibility concept for continuous component expansion.

Specifications

| Model No. | BWDW-2KN |

| Load capacity | 2KN (0.4%--100%? |

| Multiple load cell in one machine function | YES |

| Load Accuracy | Class 0.5 according ISO7500-1 |

| Load measuring resolution | 1/500000 FS, stepless |

| Position / displacement resolution | 0.001mm |

| Crosshead travel | 1150mm |

| Tensile test space | 800mm |

| Compression test space | 900mm |

| Standard tensile test fixture | Screw action grip |

| Compression platen diameter | Φ100mm |

| Testing speed range |

0.001 mm/min ? 500 mm/min, stepless, adjustable arbitrarily |

| Weight | 95kg |

| Standard Power | 220/110V, 50/60HZ, 1 phase |

| Dimensions | 520×410×1500mm |

| Analysis software | SmartTest English version |

| Working system | MS Win7 / Win10 |

|

Specifications: - Load measurement accuracy: +/- 0.5% of applied load from 2% to 100% capacity; extended range down to 1% capacity with accuracy of 1% of applied load Position measurement accuracy: +/- 0.01% of reading or 0.001 mm, whichever is greater Deformation measuring accuracy and measuring range: 2%?100%FS, ≤±0.5% Strain measurement accuracy: +/- 0.5% of indicated load from 0.2% to 100% capacity FS Speed accuracy: ±1%(0.001~10mm/min),±0.5%(10~500mm/min) Operating temperature range: 0 to 38 degrees C (32 to 100 degrees F) Storage temperature range: -10 to 45 degrees C (14 to 115 degrees F) Humidity range: 10% to 90% non-condensing, wet bulb method Power: standard optional voltages110/220VAC, 50-60 Hz; power must be free of spikes and surges exceeding 10% of the nominal voltage. |

|

Accessories

Software Description

Download Cataloge

ENQUIRY

Computerized Universal Testing Machine with Single Column Servo

Description

This is hydraulically controlled servo Universal Testing Machine. The main advantage of this servo system is a test can be conducted by giving a specific load rate or elongation rate. The oil flow is controlled by the close loop feedback from the load elongation system. Test with specific load steps can also be conducted.

Application

Features

Universal Testing Machines have a wide range of applications and number of materials, metals in different form and shapes can be tested for variety of tests like Tension, Compression, Transverse, Bend, Shear, Brinell Hardness etc. Special attachments are also available for testing of Flat Belts, Chain Links, Wire Ropes etc.

Specifications

| Model No. | BCF-UTM-1200 HG | BCF-UTM-1500HG |

| Measuring Cap. (kN) | 1200 | 1500 |

| Measuring Range. (kN) | 0-1200 | 0-1500 |

| Least Count (kN) | 0.06 | 0.075 |

|

Load Range in kN with accuracy of Measurement ± 1% |

24 to 1200 | 30 to 1500 |

| Resolution of Piston movement (mm) | 0.01 | 0.01 |

| Max. tensile clearance at fully descended piston position | 50 to 850 | 50 to 850 |

| Maximum clearance for Compression test (mm) | 0-850 | 0-850 |

| Distance between columns (mm) | 750 | 800 |

| Piston Stroke (mm) | 250 | 275 |

| Maximum straining speed at no load (mm/min) | 80 | 60 |

| Power Supply | 3 Phase 415 V 50 Piz A.C | |

| H. P. (Total) | 4.0 | 6.5 |

|

Overall dimensions (Approx) (mm L x W x H) |

2350 x 800 x 2700 | 2600 x 1000 x 3200 |

| Weight (Approx in kg) | 4500 | 7500 |

Accessories

| Model No. | BCF-UTM- 1200 HG | BCF-UTM- 1300 HG |

| Tension Test JAWS For : | ||

| Round specimen dia (mm) | 10 - 25 | 10-25 |

| Round specimen dia (mm) | 25-45 | 25-45 |

| Round specimen dia (mm) | 45-70 | 45-75 |

| Flat specimen Thickness (mm) | 0-22 | 0-22 |

| Flat specimen Thickness (mm) | 22-44 | 22-44 |

| Flat specimen Thickness (mm) | 44-65 | 44-70 |

| Max. width for Flat specimen (mm) | 70 | 75 |

| For Compression Test: | ||

| Pair of Compress Plates dia Ø(mm) | 160 | 180 |

| For Transverse Test: | ||

| Adjustment roller supports width (mm) | 160 | 160 |

| Diameter (mm) | 50 | 50 |

| With Max. adjustable clearance (mm) | 800 | 800 |

| Punch Taps of Radius (mm) | 16 | 16 |

| Radius (mm) | 22 | 22 |

Software Description

Download Cataloge

ENQUIRY

Computerized Universal Testing Machine Front Open With Hydraulic Grip

Description

Application

Features

Universal Testing Machines have a wide range of applications and number of materials, metals in different form and shapes can be tested for variety of tests like Tension, Compression, Transverse, Bend, Shear, Brinell Hardness etc. Special attachments are also available for testing of Flat Belts, Chain Links, Wire Ropes etc.

LOADING FRAME:

The base has a hydraulic cylinder at its center and two main screws at both ends. The middle cross head is mounted on screws through main nuts. The middle cross head can be moved up or down through chain transmission and geared motor to adjust the initial tensile/compression clearance. Inside base of machine, hydraulic cylinder is sestet in which piston is placed on the piston, rests an assembly of upper, lower cross head and two columns. The individually lapped cylinder piston assembly ensures smooth axial force with minimum friction.

CONTROL PANEL:

Hydraulic circuit it consists of hydraulic power pack which has a directly driven radial plunger pump which gives continuous non-pulsating flow of oil pressure up to 250bar a pressure compensated needle type flow control valve is obtained with help of valves Optionally this. can be controlled form electronic system.

LOADING RATE / STRAINING RATE CONTROL:

This is superfine controlling system which controls loading rate / straining rate as per commands from electronic machine control system. FINE UTM Software can send loading rate / straining rate to electronic system for fully automatic testing.

LOAD MEASUREMENT SYSTEM:

Oil pressure in the main cylinder is also transferred to an electronic pressure transducer which gives proportionate signal to electronic unit. Both the motors for hydraulic operation and cross head motion are controlled by buttons on electronic control system and they have interlocked to prevent simultaneous working of motors. The electrical panel is housed in control panel. Displacement measurement is carried out by means of a rack and pinion on rotary encoder. Encoder signal is fed to electronic system to get displacement.

OPERATION:

Tension test is conducted by gripping the test specimen in the upper and middle cross head. Compression, Bending, Transverse, Shear and Hardness tests are conducted between the middle and lower cross head by using appropriate fixtures. The rapid adjustment of middle crosshead facilitates easy fixing of tensile / Compression specimens of different lengths.

Hydraulic controls are through hand operated valve, ergonomically placed for ease of control. Optionally valves can be controlled form electronic control system. Adequate safeties for over load and over travel are incorporated and emergency switch is provided.

ACCURACY & CALIBRATION:

Every machine is calibrated in accordance with procedure laid down in BS-1610-1964 IS 1828-1991. 'Banbros' Computerized Universal Testing Machines comply with grade A of BS 1610-1964 and Grade 1.0 of IS 1828-1991. An accuracy of ± 1% guaranteed from 2% to 100% of capacity of the machine. In the computerized UTM, the computer is an integral part of the entire system and not just on ADD ON feature. This puts a lot of power and versatility into the hands of the operator and makes the system much more self-contained than usual, as it includes many functions usually only available as additional (often expensive) optional features.

Specifications

| Model No. |

BCF-UTM- 1200 |

BCF-UTM- 1500 |

| Measuring Cap. (kN) | 1200 | 1500 |

| Measuring Range. (kN) | 0-1200 | 0-1500 |

| Least Count (kN) | 0.06 | 0.075 |

|

Load Range in kN with accuracy of Measurement ± 1% |

24 to 1200 | 30 to 1500 |

|

Resolution of Piston movement (mm) |

0.01 | 0.01 |

|

Max. tensile clearance at fully descended pistonposition |

50 to 850 | 50 to 850 |

|

Maximum clearance for Compression test (mm) |

0-850 | 0-850 |

|

Distance between columns (mm) |

750 | 800 |

| Piston Stroke (mm) | 250 | 275 |

|

Maximum straining speed at no load (mm/min) |

80 | 60 |

| Power Supply | 3 Phase 415 V 50 Piz A.C | |

| H. P. (Total) | 4.0 | 6.5 |

|

Overall dimensions (Approx) (mm L x W x H) |

2350 x 800 x 2700 | 2600 x 1000 x 3200 |

| Weight (Approx in kg) | 4500 | 7500 |

Accessories

| Model No. |

BCF-UTM- 1200 |

BCF-UTM- 1500 |

| Tension Test JAWS For : | ||

| Round specimen dia (mm) | 10 - 25 | 10-25 |

| Round specimen dia (mm) | 25-45 | 25-45 |

| Round specimen dia (mm) | 45-70 | 45-75 |

|

Flat specimen Thickness (mm) |

0 - 22 | 0-22 |

|

Flat specimen Thickness (mm) |

22-44 | 22-44 |

|

Flat specimen Thickness (mm) |

44-65 | 44-70 |

|

Max. width for Flat specimen (mm) |

70 | 75 |

| For Compression Test: | ||

|

Pair of Compress Plates dia Ø(mm) |

160 | 180 |

| For Transverse Test: | ||

|

Adjustment roller supports width (mm) |

160 | 160 |

| Diameter (mm) | 50 | 50 |

|

With Max. adjustable clearance (mm) |

800 | 800 |

| Punch Taps of Radius (mm) | 16 | 16 |

| Radius (mm) | 22 | 22 |

Software Description

Download Cataloge

ENQUIRY

Computerized Universal Testing machines

Description

BWDT- 5KN Computer Control Electronic Universal Testing Machine made by Banbros range from 100N to 600KN load capacity with various models like single columns, table type, door frame type etc., is used to perform tension, compression, flexure/bending, shearing, peeling etc., test for metal and nonmetal specimens.

Matched with Banbros design and produced various test fixture, like peel, flexure, puncture, tear, pneumatic grip, belt tension etc., this UTM can be used to almost all materials include but not limited to steel rod, rubber, steel wire, plastic, seat belt, textile, wood, panel etc., mechanical performance inspection.

Load weighing system meets or exceeds the requirements of the following standards: ASTM E4, EN10002-2, BS 1610, DIN 51221, ISO 7500-1.

Application

Widely used for industrial application, factory quality control, science and research institute, QC &QA college student training, education institute, testing and inspection center, laboratories, construction company, aerospace, mechanical production, electric appliance fields.

Comply with different standards such as ASTM D638, ASTM D695, ASTM D790, ASTM D412, 624, ASTM D882, ISO 527, ISO 37, ISO 604, ISO 178 and other equivalent BS, ASTM, JIS standard.

Features

LOAD FRAME AND DRIVEN TYPE

- Compact construction applies aluminium alloy profile load frame cover structure

- Frame are proof loaded to 200% of capacity, with concentric arrangement of the drive lead screw and crosshead guide which assure high accuracy and strong reliability.

- Top and middle crosshead processed through shot blasting & baking paint technology, appearance, no corrosion and no need lubrication oil maintenance.

- Adopt Japan Panasonic/FUJI AC servo motor and driving system, ensure transmission and moment of force stable.

- Adopt Circular Arc Profile Synchronous Belt Transmission, eliminate dual direction clearance, prolongs the life of synchronous belt.

- Multiple load cell in one machine available.

- Advanced USA Vishay celtron load cell ensure the force measuring accuracy and repeatability, Overload capacity 150%.

- Compatibility concept for continuous component expansion

Specifications

| Model No. | BWDT-5KN |

| Load capacity | 5KN (0.4%--100%? |

| Multiple load cell in one machine function | YES |

| Load Accuracy | Class 0.5 according ISO7500-1 |

| Load cell overload capacity | 150% of rate capacity |

| Load measuring resolution | 1/500000 FS, stepless |

| Position / displacement resolution | 0.001mm |

| Crosshead travel | 1200mm |

| Tensile test space | 1000mm |

| Compression test space | 1000mm |

| Effective test width | 400mm |

| Standard tensile test fixture | Screw action grip |

| Compression platen diameter | Φ100mm |

| Testing speed range | 0.0001 mm/min?1270 mm/min, stepless, adjustable arbitrarily |

| Return speed | 1270mm/min |

| Weight | 160kg |

| Standard Power | 220/110V, 50/60HZ, 1 phase |

| Dimensions | 650x540x1350 |

| Analysis software | Smart Test English version |

| Working system | MS Win7 / Win10 |

|

Specifications: - Load measurement accuracy: +/- 0.5% of applied load from 2% to 100% capacity; extended range down to 1% capacity with accuracy of 1% of applied load Position measurement accuracy: +/- 0.01% of reading or 0.001 mm, whichever is greater Deformation measuring accuracy and measuring range: 2%?100%FS, ≤±0.5% Strain measurement accuracy: +/- 0.5% of indicated load from 0.2% to 100% capacity FS Speed accuracy: ±1%(0.001~10mm/min), ±0.5%(10~500mm/min) Operating temperature range: 0 to 38 degrees C (32 to 100 degrees F) Storage temperature range: -10 to 45 degrees C (14 to 115 degrees F) Humidity range: 10% to 90% non-condensing, wet bulb method Power: standard optional voltages110/220VAC, 50-60 Hz; power must be free of spikes and surges exceeding 10% of the nominal voltage. |

|

Accessories

Software Description

Download Cataloge

ENQUIRY

Computer Control Electronic Universal Testing Machine

Description

This machine is a new material testing machine combining electronic technology with software technology and mechanical transmission. It adopts stepper motor as precision power source. It adopts imported precision ball drive screw and guide rod, adopting imported grade 0.5. The precision force value sensor is then accurately measured by a high-precision force value measurement system. This series of models adopts single space structure, which is mainly used for material testing with load less than 10kN. It has firm structure, convenient operation and simple maintenance. It is an ideal test instrument for mechanical testing in various factories and enterprises. It has a wide and accurate loading speed and force range. It has high precision and sensitivity for measurement and control of load, deformation and displacement. It has stress, strain and displacement modes, and can find the maximum force value, tensile strength and bending strength, compression strength, modulus of elasticity, elongation at break, yield strength and other parameters, suitable for tensile, compression, peeling, tearing, shearing, etc. mechanical properties test and analysis.

Application

Rubber and plastics; metrological quality inspection; commodity inspection and arbitration; technical supervision department; colleges and universities; scientific research laboratory; basic materials laboratory; metallurgical steel; machinery manufacturing; electronic appliances; automobile production; textile chemical fiber; wire and cable; packaging materials and food; Instrumentation; medical equipment; petrochemical; civil nuclear energy; aerospace; ceramic materials; magnetic materials industry; energy batteries; basic materials;

Features

- Meet most of the mechanical properties test

- Completely compact structure, high rigidity design, durable

- Easy to operate, anyone can operate

- High accuracy, certified by a third-party testing agency

- High speed, low vibration, low noise motor drive

- Multilingual application function, adapt to different countries’ using

- Capabilities with graph, data sheet, report viewing and printing

- Automatic returning function after test completed

- Automatic calculation of maximum force, minimum force, average force, maximum deformation, elongation, strength, etc.

- Has a variety of curve modes such as stress-strain, force-displacement, force-time, intensity-time

- Has test mode functions such as tensile, flexural, compressive, flexural, adhesive, tear, peel, elongation, etc.

- With mechanical travel switch; emergency stop switch; over current, over voltage, under current, under voltage, leakage overload protection; software overload limit protection; breakpoint shutdown protection and other multiple protection devices

- Optional: small deformation metal extensometer, large deformation displacement tracker

Specifications

|

Model |

BSTUM-SERIES | ||||||||

| BSTUM-0.05KN | BSTUM-0.1KN | BSTUM- 0.2KN | BSTUM-0.5 KN | BSTUM-1KN | BSTUM-2KN | BSTUM-5KN | BSTUM-10KN | ||

| Capacity | KN | 0.05 Kn | 0.1 Kn | 0.2 Kn | 0.5 Kn | 1 Kn | 2 Kn | 5 Kn | 10 Kn |

| KG | 5kg | 10kg | 20kg | 50kg | 100kg | 200kg | 500kg | 1000kg | |

|

Unit switching Standard |

G, Kg, lb, N, KN STM, ISO, DIN, GB and other international standards. |

||||||||

| Displacement unit switching | Inch cm mm | ||||||||

| Test machine level | 1class | ||||||||

| Effective force range | 0.4??100?FS | ||||||||

| Force accuracy | Within ±0.5% | ||||||||

| Force decomposition | 1/200 000 | ||||||||

| Force Power magnification | 1, X2, X5, X10, X20, X50, X100., etc. Seven-speed automatic shifting | ||||||||

| Displacement resolution | 0.05mm | ||||||||

| Displacement accuracy | Within ±1% | ||||||||

|

Deformation measurement range |

2%?100%FS | ||||||||

| Deformation indication accuracy | Within ±1% | ||||||||

| Large deformation measurement range | (0?800)mm | ||||||||

| Large deformation resolution | 0.05mm | ||||||||

| Large deformation indication error limit | Within ±1% | ||||||||

| Maximum test speed | 500mm/min?optional maximum 1000mm/min | ||||||||

| Minimum test speed | 0.1mm/min | ||||||||

| Speed accuracy | Within ±1% | ||||||||

|

Beam travel standard height optional |

No grip testing stroke?920mm No grip testing stroke?1320mm |

||||||||

| Fixture configuration | One set of tensile grip?can choose other grips | ||||||||

| Returning method | Manual or automatic selection, automatically return after the test ends or manually return to the initial position | ||||||||

| Stop method |

1.Maximum break value automatically stop 2.Upper and lower limit safety setting stop |

||||||||

| Safety devices |

1.Mechanical limit switch protection 2.Emergency stop switch emergency brake |

||||||||

| Overload protection | Over 10% of maximum load, automatic machine protection | ||||||||

| Accessories | 1 power cord; 1 manual; 1 certificate | ||||||||

| Optional accessories | Anti-splash device (protective door); printer; software | ||||||||

| Powder supply | 220V.AC/ 50HZ; 110V.AC/60HZ | ||||||||

| Main host size/ weight |

Standard model: Length*Width*Height:450mm*400mm*1160mm / Around 50KG Heightening model: Length*Width*Height:450mm*400mm*1550mm / Around 55KG |

||||||||

| Packing size / weight |

Standard model: Length*Width*Height:550mm*500mm*1400mm / Around 73KG Heightening model: Length*Width*Height:550mm*500mm*1800mm / Around 78KG |

||||||||

Accessories

Software Description

Download Cataloge

ENQUIRY

Single Column Touch Screen Electronic Universal Testing Machine

Description

BANBROS BCUM-(S)Series electromechanical universal testing machines can perform a wide range of mechanical tests including tensile, compression, bend, peel, tear, friction, and shear testing. These systems are designed to test materials, components, and products in accordance with ASTM, ISO, and other industry standards. Compatible with hundreds of accessories for a wide range of applications, these universal testing systems are available in a multiple sizes and configurations for R&D, QC, and other mechanical testing up to 200 kN force.

Application

Features

Specifications

| Model No. | BCUM- 1KN(S) |

BCUM- 2.5KN(S) |

BCUM- 5KN(S) |

BCUM- 10KN(S) |

BCUM- 25KN(S) |

BCUM- 50KN(S) |

BCUM- 100KN(S) |

BCUM- 200KN(S) |

| Load capacity | 1Kn | 2.5kN | 5Kn | 10Kn | 25Kn | 50Kn | 100Kn | 200Kn |

| Load L.C. | 0.1N | 1N | 0.005kN | 0.01kN | ||||

| Grip Separation Min-Max |

0-300mm | 0-800mm | ||||||

| Compression space |

300mm | 800mm | ||||||

| Testing Speed | Step-less speed of 0.5 to 500mm/min | |||||||

| Elongation L.C. | 0.1mm with digital optical encoder | |||||||

| Motor capacity | 0.5kw | 0.75kw | 1kw | 2kw | ||||

| Input Power | Single phase 220V 50Hz | |||||||

| Safety Feature | Emergency Stop, Over-travel protection, Over load protection & Auto Break judgment provided with each model | |||||||

| Design Feature | Heavy duty ‘Best in class’ twin guided double pillar design for best stability and higher stiffness | |||||||

Accessories

Software Description

- Pc Based Dynamic Software.

- Fully Pc Controlled Software.

- Protection With A Password To Avoid Misuse.

- Real Time Graph.

- Load Vs Displacement Graph.

- Load Vs Time Graph.

- Displacement Vs Time Graph.

- Stress Vs Strain Graph.

- Single Test And Single Report.

- Multi Test And Multi Report.

- Staststical Analyse Of Multi Report.

- Test Report During Test.

- Test Reports Re Call Facility From History.

- Data Back Up And Restore Facility.

- Customer End Report Generation.

- Reports Saved As Word, Excel And Pdf Format.

- This Software Supports Windows 7,8,10,11,

Download Cataloge

ENQUIRY

Servo Control Computerized Universal Testing Machine

Description

BANBROS BCUM-Series electromechanical universal testing machines can perform a wide range of mechanical tests including tensile, compression, bend, peel, tear, friction, and shear testing. These systems are designed to test materials, components, and products in accordance with ASTM, ISO, and other industry standards. Compatible with hundreds of accessories for a wide range of applications, these universal testing systems are available in a multiple sizes and configurations for R&D, QC, and other mechanical testing up to 100 kN force.

Application

Features

Specifications

| Model No. | BCUM-0.5KN | BCUM-1KN | BCUM-2.5KN | BCUM-5KN | BCUM-10KN | BCUM-25KN | BCUM-50KN | BCUM-100KN |

| Load capacity | 0.5Kn | 1Kn | 2.5kN | 5Kn | 10Kn | 25Kn | 50Kn | 100Kn |

| Load L.C. | 0.1N | 1N | 0.01Kn | 0.1Kn | ||||

| Grip Separation Min-Max | 0-300mm | 0-800mm | ||||||

| Compression space | 300mm | 800mm | ||||||

| Testing Speed | Step-less speed of 2.5 to 25mm/min OR 5 to 50mm/min OR 10 to 100mm/min OR 50 to 500mm/min | |||||||

| Elongation L.C. | 0.1mm with digital rotary encoder | |||||||

| Motor capacity | 0.5hp | 1hp | 2hp | 3hp | ||||

| Input Power | Single phase 220V 50Hz | Three phase 440V 50Hz | ||||||

| Safety Feature | Overload Protection | Emergency Stop, Over-travel protection, Over load protection & Auto Break judgement provided with each model | ||||||

| Design Feature | Heavy duty ‘Best in class’ twin guided double pillar design for best stability and higher stiffness | |||||||

Accessories

Software Description

- Pc Based Dynamic Software.

- Fully Pc Controlled Software.

- Protection With A Password To Avoid Misuse.

- Real Time Graph.

- Load Vs Displacement Graph.

- Load Vs Time Graph.

- Displacement Vs Time Graph.

- Stress Vs Strain Graph.

- Single Test And Single Report.

- Multi Test And Multi Report.

- Staststical Analyse Of Multi Report.

- Test Report During Test.

- Test Reports Re Call Facility From History.

- Data Back Up And Restore Facility.

- Customer End Report Generation.

- Reports Saved As Word, Excel And Pdf Format.

- This Software Supports Windows 7,8,10,11,

Download Cataloge

ENQUIRY

Computerized Universal Testing Machine

Description

BANBROS BDUM-Series electromechanical universal testing machines can perform a wide range of mechanical tests including tensile, compression, bend, peel, tear, friction, and shear testing. These systems are designed to test materials, components, and products in accordance with ASTM, ISO, and other industry standards. Compatible with hundreds of accessories for a wide range of applications, these universal testing systems are available in a multiple sizes and configurations for R&D, QC, and other mechanical testing up to 100 kN force.

Application

Features

Specifications

| Model No. | BDUM-0.5KN | BDUM-1KN | BDUM-2.5KN | BDUM-5KN | BDUM-10KN | BDUM-25KN | BDUM-50KN | BDUM-100KN |

| Load capacity | 0.5Kn | 1Kn | 2.5kN | 5Kn | 10Kn | 25Kn | 50Kn | 100Kn |

| Load L.C. | 0.1N | 1N | 0.01Kn | 0.1Kn | ||||

| Grip Separation Min-Max | 0-300mm | 800mm | ||||||

| Compression space | 300mm | 800mm | ||||||

| Testing Speed | Step-less speed of 2.5 to 25mm/min OR 5 to 50mm/min OR 10 to 100mm/min OR 50 to 500mm/min | |||||||

| Elongation L.C. | 0.1mm with digital rotary encoder | |||||||

| Motor capacity | 0.5hp | 1hp | 2hp | 3hp | ||||

| Input Power | Single phase 220V 50Hz | Three phase 440V 50Hz | ||||||

| Safety Feature | Overload Protection | Emergency Stop, Over-travel protection, Over load protection & Auto Break judgement provided with each model | ||||||

| Design Feature | Heavy duty ‘Best in class’ twin guided double pillar design for best stability and higher stiffness | |||||||

Accessories

Software Description

Download Cataloge

ENQUIRY

Digital Universal Testing Machine

Description

United Test make Universal Testing Machines are known for their long-lasting trouble-free performance and highest quality material used in the manufacturing process. The Hydraulic universal testing machine can perform tension, compression, flexure/bending and shearing test for kinds of specimens. Suitable for metal and nonmetal material, such as iron, steel, steel bar, rebar, cement, concrete, rod and so on.

Specially design for production, research, student training and industrial laboratory. Available in wide range of load frame capacities (300kN to 2000kN)/ (10Ton to 200Ton) and with combination of control panels (Digital, Computerised) makes United Test product range suitable for every customer requirement. Load weighing system meets or exceeds the requirements of the following standards: ASTM E4, EN10002-2, BS 1610, DIN 51221, ISO 7500-1.

Application

Widely used for industrial application, factory quality control, science and research institute, QC &QA college student training, education institute, testing and inspection centre, laboratories, construction company, aerospace, mechanical production, electric appliance fields

Features

Specifications

| Model No. | BWAW-C-600KN |

| Max. load | 600KN |

| Structure | C type, Adopt Japan Shimadzu technology, worm wheel and wormshaft to drive crosshead up and down; |

| Measuring force range | 2%~100% |

| Accuracy of load | ±1% of indicated value |

| Accuracy Of Deformation | ±0.5%, resolution: 0.01mm |

| Constant load, Range | 0.4%~100%FS |

| Deformation measuring | Clip-on extensometer, standard gauge 50mm, extension 5/10/25mm |

| Column Interval Distance | 0.1 620mm |

| Effective test width space | 520mm |

| Max. tensile space | 800mm |

| Max. compression space | 700mm |

| Flat specimen range | 0~30mm |

| Round specimen range | Φ13~φ40mm |

| Compression platen | Dia. 200mm |

| Bending support roller distance | 600 mm |

| Bending roller width | 160mm |

| Bending roller dia. | 30mm |

| Piston stroke | 250mm |

| Max. piston speed | 100mm/min |

| Clamping mode | Hydraulic automatic |

| Dim. of frame | 950×580×2350mm |

| Dim. of control box | 1120×600×920mm |

| Weight | 2700kg |

Accessories

| High Stiffness Frame (C type) | 1 set |

| Controlled box (Oil cabinet) | 1 set |

| Oil Pressure sensor (600KN) | 1 set |

| Hydraulic power system | 1 set |

| High-precision electro-hydraulic proportion servo valve | 1 set |

| (Optional )Accuracy imported MOOG servo valve | |

| Photoelectric encoder for displacement | 1 set |

| Tension test clamping body (half open crosshead) | |

| Flat Jaw (0~15mm, 15-30mm); | Each 1 set |

| Round Jaw(Φ13-Φ26, Φ26-Φ40) | Each 1 set |

| Compression test fixture (Dia. 200mm) | 1 set |

| Bending Accessories | 1 set |

| Extensometer | 1 set |

| Tool kit (screwdriver, spanner etc.,) | 1 set |

| Professional testing software (SmartTest, English version) | 1 set |

| Metal tensile testing method (ISO 6892); | |

| Compression testing method (ASTM E9); | |

| Customize testing method function available. | |

| Computer (HP or LENOVO computer, 19-inch LCD monitor, | 1 set |

| English Win7 system) | |

| Printer (HP A4 color inkjet printer) | 1 set |

| Documents (Manual, packing list, certificate) |

Software Description

Download Cataloge

ENQUIRY

Computer Control Hydraulic Servo Universal Testing Machine

Description

The furnace has a columnar split structure, three stage control function. Mainly consists of furnace, temperature controller, high temperature pull rod, high temperature clamp, high temperature extensometer and supporting device. The temperature controller adopts PID mode, this mode ensures the high control accuracy. It's an ideal test equipment for high performance material of colleague, research institute, factory and so on. This furnace can work with universal testing machine, to do kinds of metal, non-metal materials high temperature tensile testing.

Application

Features